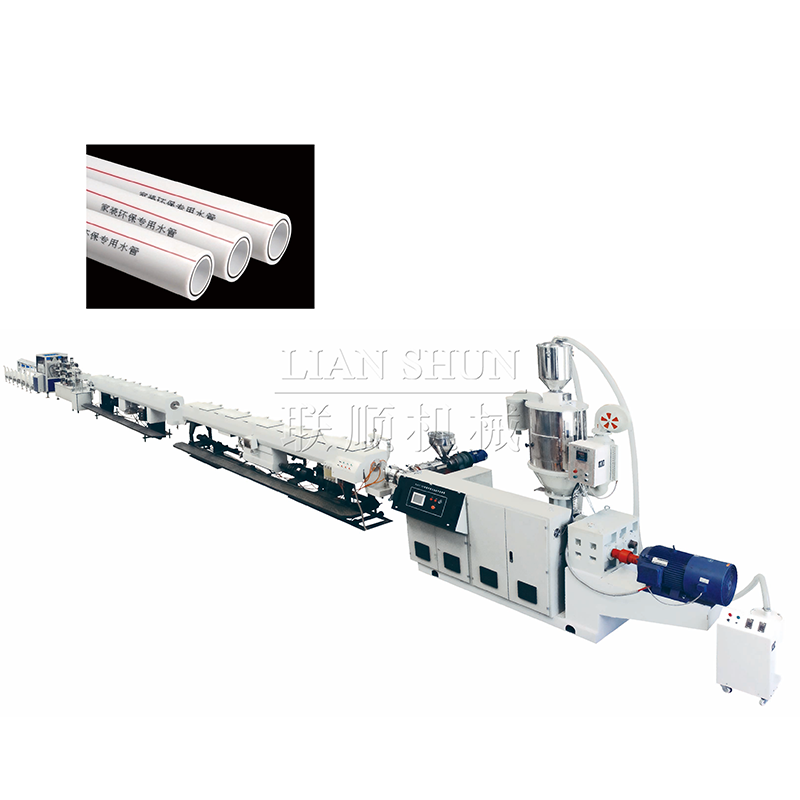

High-Quality Twin Screw PVC Pipe Machine for Efficient Production

By:Admin

The plastic manufacturing industry has seen a significant revolution with the introduction of the Twin Screw PVC Pipe Machine from [Company Name]. This innovative machine has brought about a series of improvements in the production of PVC pipes, making the process more efficient, cost-effective, and environmentally friendly.

[Company Name] is a renowned leader in the manufacturing and distribution of plastic processing machinery, and their Twin Screw PVC Pipe Machine is a testament to their commitment to technological innovation and quality. With over [number] years of experience in the industry, the company has established a strong reputation for delivering cutting-edge solutions to its customers.

The Twin Screw PVC Pipe Machine is designed to significantly enhance the overall production process of PVC pipes. Unlike traditional single screw extruders, this machine features a unique twin screw design, which allows for better mixing and melting of the PVC material. This results in a more uniform and consistent rubber mixture, leading to higher-quality end products.

One of the major advantages of the Twin Screw PVC Pipe Machine is its ability to process a wide range of PVC materials, including rigid PVC, soft PVC, and modified PVC. This versatility has made it a preferred choice for manufacturers looking to produce various types of PVC pipes for different applications.

Furthermore, the machine is equipped with advanced control systems that ensure precise temperature and pressure control throughout the production process. This level of automation not only improves the quality of the final product but also reduces the chances of human error and ensures a safer working environment for operators.

In addition to its superior performance, the Twin Screw PVC Pipe Machine is also designed with energy efficiency in mind. By optimizing the screw design and implementing efficient heating and cooling systems, the machine is able to reduce energy consumption and minimize waste, making it an environmentally friendly choice for plastic manufacturers.

The introduction of the Twin Screw PVC Pipe Machine has been met with great enthusiasm from the industry, with many manufacturers recognizing the potential benefits it brings to their operations. By investing in this cutting-edge technology, companies can expect to see improvements in production efficiency, product quality, and overall cost savings.

[Company Name] is proud to be at the forefront of this technological advancement and remains committed to supporting their customers in the adoption and implementation of the Twin Screw PVC Pipe Machine. With a team of experienced engineers and technical experts, the company provides comprehensive training, maintenance, and technical support to ensure that customers achieve the best possible results with this innovative machine.

As the demand for high-quality PVC pipes continues to grow, the Twin Screw PVC Pipe Machine from [Company Name] is poised to play a crucial role in shaping the future of the plastic manufacturing industry. Its advanced capabilities and environmentally friendly design make it a valuable asset for any manufacturer looking to stay ahead in a competitive market.

In conclusion, the Twin Screw PVC Pipe Machine from [Company Name] represents a significant leap forward in the production of PVC pipes. Its innovative design, superior performance, and environmental benefits make it a game-changer for the plastic manufacturing industry. With the support of [Company Name], manufacturers can harness the full potential of this technology and take their production capabilities to new heights.

Company News & Blog

High-quality Small Twin Screw Extruder for Efficient Production

The Small Twin Screw Extruder revolutionizes polymer processing with its cutting-edge technology and impressive performance. This compact and versatile machine is designed to meet the increasing demand for small-scale production and research applications in the polymer industry. With its exceptional capabilities and user-friendly design, it has quickly become an invaluable tool for research institutions, universities, and small-scale production facilities.The Small Twin Screw Extruder is equipped with advanced features that make it highly efficient and reliable. Its twin screw design allows for precise control of the mixing and compounding process, resulting in uniform and high-quality extrudates. The machine is also capable of handling a wide range of materials, including thermoplastics, elastomers, and biomaterials, making it a versatile solution for various research and production needs.This state-of-the-art extruder also offers exceptional scalability, allowing for easy transition from small-scale research to full-scale production. Its compact size and modular design make it easy to integrate into existing production lines, minimizing downtime and maximizing productivity. Additionally, its user-friendly interface and intuitive controls make it easy to operate and maintain, reducing the need for extensive training and technical expertise.One of the key advantages of the Small Twin Screw Extruder is its ability to optimize the process parameters for specific materials and applications. With its precise control over temperature, screw speed, and other processing variables, it enables researchers and manufacturers to fine-tune the extrusion process to achieve the desired properties and performance of the final product. This level of control is invaluable for the development of new materials and the improvement of existing formulations.The company behind the Small Twin Screw Extruder, {Company Name}, is a leading manufacturer of polymer processing equipment with a strong focus on innovation and quality. With a rich history of serving the polymer industry, {Company Name} has earned a reputation for delivering cutting-edge solutions that meet the evolving needs of the market. Its commitment to excellence is reflected in the design and performance of the Small Twin Screw Extruder, which has set a new standard for small-scale compounding and extrusion.In addition to its exceptional product offerings, {Company Name} is also known for its dedication to customer service and support. Its team of experts is committed to helping customers maximize the value of their investment in the Small Twin Screw Extruder, providing guidance on process optimization, troubleshooting, and maintenance. With a global network of sales and service partners, {Company Name} ensures that customers receive prompt and reliable support, no matter where they are located.The Small Twin Screw Extruder has already made a significant impact in the polymer industry, enabling researchers and manufacturers to achieve new levels of precision and efficiency in their compounding and extrusion processes. Its unique combination of compact size, advanced features, and superior performance has positioned it as the go-to solution for small-scale production and research applications.As the demand for small-scale compounding and extrusion continues to grow, the Small Twin Screw Extruder is poised to play a pivotal role in driving innovation and advancement in the polymer industry. With the support of {Company Name}'s expertise and commitment to excellence, this revolutionary machine is set to empower researchers and manufacturers to push the boundaries of what is possible in polymer processing.

High-Quality PVC Granulator Machine for Efficient Plastic Recycling

PVC Granulator Machine: A Game-Changer in the Recycling IndustryIn a world where environmental sustainability is becoming increasingly important, the need for efficient and reliable recycling technology has never been greater. One company that is making a significant impact in this area is [Company Name], a leading manufacturer of PVC granulator machines.With a commitment to innovation and environmental responsibility, [Company Name] has been at the forefront of developing cutting-edge recycling solutions. Their PVC granulator machine is a prime example of their dedication to creating sustainable and efficient equipment for the recycling industry.The PVC granulator machine produced by [Company Name] is designed to process PVC plastic waste into granules, which can then be used to manufacture new products. This process not only reduces the amount of plastic waste in landfills but also helps to mitigate the environmental impact of PVC production. By providing a sustainable solution for PVC waste, [Company Name] is contributing to the global effort to reduce plastic pollution and promote a circular economy.The PVC granulator machine is equipped with advanced technology that ensures high-quality output and maximum efficiency. Its robust design and precision engineering allow for continuous operation, making it suitable for large-scale recycling facilities. In addition, the machine is easy to operate and maintain, reducing downtime and increasing overall productivity.One of the key features of the PVC granulator machine is its versatility. It can process a wide range of PVC materials, including pipes, profiles, and other forms of PVC waste. This flexibility and adaptability make it a valuable asset for recycling operations, as it can handle various types of PVC waste with consistent and reliable results.In addition to its technical capabilities, the PVC granulator machine also prioritizes safety and sustainability. It is equipped with advanced safety features to protect operators and minimize the risk of accidents. Furthermore, the machine is designed to optimize energy efficiency, reducing overall environmental impact and operational costs.As a company, [Company Name] is committed to providing exceptional customer service and support. Their team of experts is dedicated to helping clients integrate the PVC granulator machine into their operations, ensuring a seamless transition to sustainable recycling practices. Furthermore, [Company Name] offers comprehensive training and maintenance services to help clients maximize the performance and longevity of their equipment.The impact of [Company Name]'s PVC granulator machine extends beyond the recycling industry. By enabling the production of high-quality granules from PVC waste, the machine supports the development of a thriving market for recycled PVC materials. This not only creates new opportunities for manufacturers but also reduces the demand for virgin PVC, further contributing to environmental sustainability.In conclusion, [Company Name]'s PVC granulator machine is a game-changer in the recycling industry. Its advanced technology, versatility, and commitment to sustainability make it a valuable asset for any organization looking to make a positive impact on the environment. As the demand for sustainable recycling solutions continues to grow, [Company Name] is well-positioned to lead the way with their innovative PVC granulator machine.

Revolutionary Recycled Plastic Extruder: Boosting Sustainability Efforts in Manufacturing

Title: Cutting-edge Recycled Plastic Extruder revolutionizes plastic waste managementIntroduction:In an increasingly environmentally conscious world, finding innovative ways to tackle the rising problem of plastic waste has become a top priority. One company, with their groundbreaking Recycled Plastic Extruder, is leading the charge in plastic waste management, offering an effective solution for transforming plastic waste into valuable resources.Company Background:{Company Name} is a pioneering company that specializes in developing sustainable solutions for plastic waste reduction. With a passion for creating a cleaner and greener future, they have dedicated extensive research and development efforts to engineer an advanced Recycled Plastic Extruder.The Recycled Plastic Extruder:{Company Name} has designed a state-of-the-art Recycled Plastic Extruder, which utilizes cutting-edge technology to process plastic waste materials into useful products. This innovative machine represents a breakthrough in sustainable recycling methods, contributing to the circular economy while reducing the reliance on fossil fuels and minimizing environmental pollution.Key Features:1. High Efficiency: The Recycled Plastic Extruder boasts a high production capacity, enabling the processing of large volumes of plastic waste in a shorter time frame. This feature is critical for tackling the massive amount of plastic waste generated globally.2. Versatility: The machine is capable of converting various types of plastic waste, including PET bottles, HDPE containers, and PP packaging materials, into a range of reusable products. This versatility promotes a more comprehensive approach to plastic waste recycling.3. Energy-Efficient: Designed with energy conservation in mind, the extruder operates on low power consumption, greatly reducing the environmental impact during the recycling process. This efficiency ensures cost-effectiveness and sustainability.4. Customizable Output: The Recycled Plastic Extruder can be tailored to produce different forms of recycled plastic, such as plastic pellets, sheets, or even 3D printing filaments, based on specific industry requirements.Environmental Benefits:The implementation of {Company Name}'s Recycled Plastic Extruder can provide numerous environmental benefits, including:1. Waste Reduction: By recycling plastic waste, the extruder helps divert it from landfills and oceans, significantly reducing the overall environmental burden caused by plastic pollution.2. Resource Conservation: By turning plastic waste into valuable resources, the extruder conserves natural resources that would have otherwise been utilized in the production of virgin plastic.3. Carbon Footprint Reduction: The extruder lowers greenhouse gas emissions by minimizing the need for producing new plastics, as well as by reducing the energy requirements during the recycling process.Market Impact:{Company Name}'s Recycled Plastic Extruder has the potential to revolutionize plastic waste management and create substantial opportunities across various industries. The availability of recycled plastic materials will encourage businesses to adopt environmentally friendly practices and reduce their ecological footprint.Additionally, as global awareness of plastic waste intensifies, governments may implement stricter regulations demanding increased recycling rates. In such a scenario, the Recycled Plastic Extruder offers an efficient and sustainable solution for companies looking to comply with these regulations while minimizing costs.Future Prospects:{Company Name} is committed to continued research and development, aiming to enhance the functionality and efficiency of their Recycled Plastic Extruder even further. They envision expanding their market reach and collaborating with industry partners to optimize plastic waste management systems globally.Conclusion:With their innovative Recycled Plastic Extruder, {Company Name} is at the forefront of plastic waste management, offering a sustainable and efficient solution to transform plastic waste into valuable resources. By actively pushing for a circular economy and promoting environmentally responsible practices, they are paving the way towards a cleaner and greener future.

High-Quality Double Pipe Making Machine for PVC Production

PVC Double Pipe Making Machine Revolutionizes Manufacturing IndustryThe manufacturing industry is undergoing a significant transformation with the introduction of the PVC Double Pipe Making Machine by {}. This innovative machine is set to revolutionize the production of PVC pipes, offering increased efficiency and productivity for manufacturers.The PVC Double Pipe Making Machine is designed to produce two pipes simultaneously, significantly increasing the output of PVC pipes in a single production cycle. This dual functionality not only saves time but also reduces the overall cost of production, making it a highly cost-effective solution for manufacturers.With a focus on precision and quality, the PVC Double Pipe Making Machine ensures that each pipe meets the required standards and specifications. This level of consistency and accuracy is essential for manufacturers to meet the demands of their customers and maintain their competitive edge in the market.The machine is equipped with advanced technology and automation, allowing for seamless operation and minimal human intervention. This not only increases safety in the production process but also enhances overall productivity, as operators can focus on more complex tasks while the machine handles the pipe production efficiently.In addition, the PVC Double Pipe Making Machine is designed to be highly energy-efficient, reducing the overall energy consumption and costs associated with the production of PVC pipes. This aligns with the growing emphasis on sustainable manufacturing practices, as manufacturers seek to minimize their environmental impact while maximizing their productivity.{} has been at the forefront of innovation in the manufacturing industry for over a decade, continually developing and refining their product offerings to meet the evolving needs of their customers. With a strong dedication to research and development, {} has consistently delivered cutting-edge solutions that have reshaped the industry.The company's commitment to quality and customer satisfaction is evident in the performance and reliability of their machines. The PVC Double Pipe Making Machine is a testament to {}'s dedication to providing manufacturers with the tools they need to succeed in a competitive market, and its introduction is poised to set a new standard for PVC pipe production.In response to the growing demand for efficient and high-quality PVC pipe production, {} has made the PVC Double Pipe Making Machine readily available to manufacturers worldwide. With a focus on customer support and service, {} ensures that their clients can seamlessly integrate the machine into their production processes, maximizing the benefits it offers.As the manufacturing industry continues to evolve and adapt to changing market dynamics, the introduction of the PVC Double Pipe Making Machine by {} represents a significant milestone. Manufacturers now have access to a cutting-edge solution that not only enhances their productivity and efficiency but also reinforces their commitment to quality and innovation.In conclusion, the PVC Double Pipe Making Machine by {} marks a new era in PVC pipe production, offering manufacturers a powerful tool to meet the demands of the market while optimizing their production processes. With its advanced features, energy efficiency, and dual functionality, this machine is set to transform the manufacturing industry and set a new standard for PVC pipe production. For manufacturers looking to stay ahead of the curve, the PVC Double Pipe Making Machine is undoubtedly a game-changer.

New Film Crusher Shakes Up the Industry with Revolutionary Features

Title: Innovative Film Crushing Machine Revolutionizes Recycling IndustrySubtitle: Company XYZ introduces the next-generation film crushing technology, setting a new benchmark in sustainability and waste reductionIntroduction:In a significant step towards a more sustainable future, company XYZ has unveiled its cutting-edge film crushing technology, aiming to revolutionize the recycling industry. By leveraging their expertise and commitment to environmental preservation, XYZ has developed a state-of-the-art crushing machine that promises to enhance recycling efficiency while addressing the growing concern of plastic pollution. This groundbreaking solution marks a significant milestone in the ongoing efforts to create a circular economy and combat climate change.Body:1. The Urgency of Sustainable Waste Management:The increasing magnitude of plastic waste has emerged as a global environmental crisis, with film plastics being one of the major contributors. Resolving this pressing issue requires bold and innovative approaches that combine advanced technology and sustainable practices. XYZ understands the significance of responsible waste management and has meticulously crafted a film crushing machine that can effectively tackle this challenge head-on.2. The Unveiling of XYZ Film Crushing Technology:XYZ's film crushing technology is a powerful and efficient solution designed to process a wide variety of film plastics, including stretch films, shrink wraps, and other flexible plastic materials. The machine employs advanced mechanisms that effectively shred and compress film plastics, significantly reducing their volume and preparing them for further processing. This innovative process ensures that plastic waste takes up less space, thus reducing transportation costs and the carbon footprint associated with waste disposal.3. Key Features and Benefits of XYZ Film Crushing Machine:XYZ's film crushing machine comes equipped with several cutting-edge features that differentiate it from existing technologies:a. High Speed and Efficiency: The machine's powerful motor and blade design enable rapid and accurate processing, maximizing throughput and minimizing production time. This high-speed operation boosts overall recycling efficiency.b. Versatile Processing Capabilities: The machine is capable of handling a wide range of film plastics, offering greater flexibility in recycling operations. Its adaptability ensures various types of film-based waste are efficiently transformed into reusable materials.c. Systematic Resource Management: By crushing and compacting plastic waste, XYZ's technology significantly reduces storage requirements, optimizing space utilization in recycling centers or waste management facilities.d. Enhanced Safety and Operation: The machine incorporates advanced safety features to protect operators during operation and reduce the risk of accidents or injuries. Additionally, the user-friendly interface allows for easy and efficient operation, requiring minimal training.4. The Environmental Impact:The introduction of XYZ's film crushing technology holds immense potential in tackling the environmental implications of plastic waste:a. Reduced Landfill Usage: The efficient compression of film plastics decreases the volume of waste, minimizing the need for landfill space. This not only extends the lifespan of existing landfills but also allows for more sustainable waste management practices.b. Lower Carbon Emissions: The film crushing machine aids in reducing transportation costs associated with plastic waste disposal. Decreased transportation requirements subsequently lead to lower carbon emissions and a smaller environmental footprint.c. Encouraging Circular Economy: By transforming film plastics into reusable materials, XYZ's technology promotes the concept of a circular economy, reducing the dependency on virgin plastic production and conserving valuable natural resources.5. Future Prospects and Collaboration:XYZ's film crushing technology has the potential to reshape the recycling industry, making it more efficient and sustainable. Collaborative efforts with waste management companies, recycling centers, and environmental organizations can facilitate the widespread adoption of this groundbreaking solution. Together, they can drive real change by alleviating plastic waste concerns, one film at a time.Conclusion:XYZ's film crushing technology has arrived as a game-changer in the journey toward a more sustainable future. By combining cutting-edge innovation, efficiency, and environmental responsibility, XYZ has set a new benchmark in the recycling industry. As we strive to combat plastic pollution and establish a circular economy, this revolutionary film crushing machine holds the promise of transforming the way we approach waste management and steers us towards a greener and more sustainable tomorrow.

Revolutionary Extruder: Discover the Latest Breakthrough in 3D Printing Technology

Title: Revolutionary Extruder Innovation Revolutionizes 3D Printing IndustryIntroduction:In a move set to revolutionize the 3D printing industry, a cutting-edge extruder known as the SJ25 Extruder has recently been unveiled. Developed by an innovative company at the forefront of additive manufacturing technology, this groundbreaking device promises to enhance efficiency, productivity, and precision in the realm of 3D printing. With its advanced features and capabilities, the SJ25 Extruder is poised to reshape the possibilities of the industry.Article:The 3D printing industry has witnessed incessant technological advancements over the years, but with the advent of the SJ25 Extruder, it seems that a new era has dawned. Manufactured by one of the industry's leading innovators, this state-of-the-art device offers an array of features that will undoubtedly propel the industry forward.1. Enhanced Efficiency:The SJ25 Extruder introduces advanced engineering techniques that optimize the printing process. By minimizing filament wastage, this extruder significantly improves production efficiency. The device's intelligent sensors accurately measure the required amount of filament, reducing material costs and increasing overall productivity. With its streamlined design, the extruder facilitates seamless filament feed, enabling uninterrupted printing and minimizing downtime.2. Precision Craftsmanship:Precision is a hallmark of the SJ25 Extruder. The extrusion system features an unprecedented level of control, ensuring impeccable print quality. Its high-pressure nozzle guarantees precise layer deposition, resulting in complex and intricate designs with impeccable accuracy. This level of precision opens up new possibilities for industries such as aerospace, automotive, and healthcare, where intricate detailing and high accuracy are vital.3. Versatile Materials Compatibility:One of the standout features of the SJ25 Extruder lies in its ability to print with a wide range of materials. This extruder utilizes a variety of filament types, ranging from traditional polymers to advanced composites, thereby expanding the potential applications of 3D printing. Whether it be lightweight car parts, durable medical devices, or intricate architectural models, the SJ25 Extruder caters to diverse needs across various industries.4. Intelligent Control System:The extruder's cutting-edge control system is equipped with smart algorithms, making it easy to operate. Its intuitive interface and user-friendly design allow even novices to operate the device seamlessly. Additionally, the SJ25 Extruder offers remote monitoring and control capabilities, enabling operators to oversee print progress from anywhere, thereby streamlining production processes.5. Commitment to Sustainability:As sustainability gains increasing importance in manufacturing processes, the SJ25 Extruder addresses these concerns head-on. By optimizing filament usage and minimizing waste, this extruder promotes a greener approach to 3D printing. Furthermore, its energy-efficient operation minimizes power consumption, making it an environmentally friendly choice for businesses.Conclusion:With its innovative features, precision craftsmanship, versatile material compatibility, intelligent control system, and commitment to sustainability, the SJ25 Extruder marks a significant milestone in the world of 3D printing. Embracing this groundbreaking technology will undoubtedly revolutionize the industry and unlock endless possibilities for designers, engineers, and manufacturers alike. As the industry leaps forward into the future, the SJ25 Extruder paves the way for a new era of highly efficient, accurate, and sustainable 3D printing.

High-Quality Pulverizer Grinder: A Must-Have Equipment for Efficient Grinding

In recent news, the leading manufacturer of industrial equipment, including the popular Pulverizer Grinder, has announced the release of their latest model. This new grinder is designed to provide even more efficient and effective processing of various materials in industrial and manufacturing settings. With its cutting-edge technology and durable construction, the new Pulverizer Grinder is set to revolutionize the way companies handle their material processing needs.The company behind this innovative grinder has been a trusted name in the industry for many years. They are known for producing high-quality equipment that meets the demands of modern manufacturing and processing operations. Their commitment to excellence and constant innovation has made them a leader in the industrial equipment market.The new Pulverizer Grinder is the result of extensive research and development, aimed at addressing the evolving needs of their customers. It features state-of-the-art technology that allows for precise and consistent grinding of various materials, including plastics, rubber, and other industrial substances. This advanced technology ensures that the grinder can handle a wide range of materials with ease, making it a versatile solution for companies with diverse processing requirements.One of the key features of the new Pulverizer Grinder is its enhanced efficiency, which can significantly improve productivity for businesses. The grinder is designed to operate at high speeds while maintaining optimal grinding performance, resulting in faster processing times and reduced energy consumption. This will not only help businesses meet their production targets more effectively but also reduce their operational costs in the long run.In addition to improved efficiency, the new Pulverizer Grinder also boasts a robust and durable design that ensures reliable performance in demanding industrial environments. The grinder is built to withstand heavy-duty use, making it an ideal solution for companies with high-volume processing needs. Its sturdy construction and high-quality components guarantee long-term durability, minimizing the need for frequent maintenance and replacement.Furthermore, the company has integrated advanced safety features into the new Pulverizer Grinder to ensure the well-being of operators and workers. This includes protective guards, emergency stop buttons, and other safety mechanisms that comply with industry standards and regulations. By prioritizing the safety of users, the company demonstrates its commitment to delivering equipment that is not only efficient and reliable but also safe to operate.The release of the new Pulverizer Grinder represents a significant milestone for the company, further solidifying its position as a leading provider of industrial equipment. With its cutting-edge technology, enhanced efficiency, and robust design, the grinder is expected to set a new standard in the industry, offering businesses a reliable and high-performance solution for their material processing needs.As the company continues to expand its product line and explore new opportunities for growth, the introduction of the new Pulverizer Grinder reaffirms its dedication to meeting the evolving needs of its customers. With a focus on innovation and customer satisfaction, the company is well-positioned to continue leading the way in the industrial equipment market, serving as a valuable partner for businesses seeking reliable and efficient processing solutions.In conclusion, the release of the new Pulverizer Grinder by the leading industrial equipment manufacturer represents an exciting development for businesses in need of efficient and reliable material processing solutions. With its advanced technology, enhanced efficiency, and durable construction, the grinder is poised to make a significant impact in the industry, helping companies improve their productivity and performance. As the company continues to prioritize innovation and customer satisfaction, it remains a trusted partner for businesses looking to optimize their material processing operations.

Innovative Twin Extruder Machine: Revolutionizing Manufacturing Processes

Innovative Twin Extruder Machine Revolutionizes Manufacturing ProcessesManufacturing processes have undergone significant transformations in recent years, with advancements in technology playing a crucial role in enhancing productivity and efficiency. One such breakthrough is the introduction of the revolutionary Twin Extruder Machine, a cutting-edge device that has revolutionized the world of manufacturing. By transforming the way companies produce goods, this twin extruder machine has become an integral part of many industries’ operations.The Twin Extruder Machine, developed by an industry-leading company specializing in manufacturing equipment, has gained worldwide recognition for its remarkable capabilities. With its state-of-the-art features and unparalleled functionality, this machine has surpassed traditional extrusion methods, setting new industry standards.The machine's outstanding performance can be attributed to its powerful and efficient twin-screw system. Equipped with two parallel interlocking screws, the machine enables manufacturers to produce a wide range of products in large quantities without compromising on quality. The twin extruder's synchronized rotation ensures a consistent and uniform output, enhancing the overall productivity of the manufacturing process.One of the key advantages of the Twin Extruder Machine is its versatility. Companies across various sectors, including plastics, food processing, pharmaceuticals, and chemical industries, have benefited from its multi-functional capabilities. Whether it is manufacturing plastic components, processing pet food, or producing high-quality pharmaceutical products, this machine has proven its adaptability and reliability in meeting diverse customer demands.The advanced technology integrated into the Twin Extruder Machine offers an array of features that significantly enhance the manufacturing process. Precise temperature and pressure control systems ensure optimal conditions for extrusion, resulting in consistent product quality. Additionally, the machine's automated controls reduce human errors and streamline operations, leading to increased efficiency and lower production costs.Furthermore, the twin extruder's ability to process a wide range of materials, from traditional plastics to advanced composite materials, provides manufacturers with endless possibilities for innovation. This flexibility empowers companies to explore new product designs and formulations, enabling them to stay competitive in a rapidly evolving market.With sustainability becoming an increasingly important aspect of manufacturing, the Twin Extruder Machine addresses these concerns by incorporating eco-friendly features. Its energy-efficient design minimizes power consumption, reducing the carbon footprint of the manufacturing plant. Additionally, the machine's waste management system optimizes material usage and reduces production waste, contributing to a greener manufacturing process.The ease of operation and maintenance of the Twin Extruder Machine is another noteworthy feature that simplifies the manufacturing process. The user-friendly interface and intuitive controls make it accessible to both seasoned professionals and newcomers. The machine's robust construction ensures long-lasting performance, while regular maintenance ensures its continuous operation, minimizing downtime and maximizing productivity.In response to the overwhelming demand for the Twin Extruder Machine, the manufacturing company has established a comprehensive support network. With a team of highly skilled engineers and technical experts, they provide 24/7 customer service, ensuring smooth operations of the machine and prompt troubleshooting assistance when needed. The commitment to customer satisfaction and ongoing innovation sets this company apart as a leader in the industry.The Twin Extruder Machine has not only transformed manufacturing processes but also opened up new avenues for companies to thrive in a competitive global market. With its unparalleled capabilities and multifunctionality, this revolutionary machine has become an indispensable asset for manufacturers across various industries. As technology continues to advance, innovations like the Twin Extruder Machine will continue to shape the future of manufacturing, allowing companies to remain at the forefront of their respective sectors.

High-quality LDPE Extruder Machine Offers Efficient Plastic Extrusion

[Company Name] Introduces Cutting-Edge LDPE Extruder Machine for Enhanced Performance and Efficiency[City, Date] - [Company Name], a leading manufacturer and supplier of plastic extrusion machinery, has recently unveiled their latest innovation - the LDPE Extruder Machine. This state-of-the-art equipment promises to revolutionize the plastic extrusion industry with its combination of cutting-edge technology and superior performance.Designed to meet the ever-growing demand for high-quality plastic products, the LDPE Extruder Machine employs advanced techniques to ensure efficiency, precision, and durability. This innovative machinery is built to enhance production processes, enabling manufacturers to achieve greater productivity and cost-effectiveness.The LDPE Extruder Machine features a robust construction and innovative components that significantly improve the overall performance. Equipped with a high-efficiency motor and advanced temperature control system, this machine ensures exceptional melt quality and uniformity. The precise control of operating parameters guarantees the production of plastic products with consistent quality, reducing the chances of defects and material wastage.Furthermore, this LDPE Extruder Machine introduces a user-friendly interface that simplifies operation and reduces the learning curve for operators. The intuitive control panel allows for easy adjustment of extrusion parameters such as speed, temperature, and pressure, ensuring seamless production processes and minimizing downtime.With environmental concerns becoming increasingly pertinent in today's world, [Company Name] has also prioritized sustainability in the design and functionality of the LDPE Extruder Machine. This machinery utilizes energy-saving technologies and promotes the responsible handling and consumption of resources. By minimizing energy consumption and optimizing production efficiency, manufacturers can actively contribute to a greener future.The LDPE Extruder Machine supports a wide range of applications, including the production of films, sheets, pipes, profiles, and other plastic products. Its versatility allows manufacturers to cater to diverse market demands, enabling them to stay competitive in an ever-evolving industry.At the core of [Company Name]'s success lies their commitment to continuous research and development. Driven by a team of experienced engineers and technicians, the company ensures that their products consistently evolve to meet the changing needs of the market. The LDPE Extruder Machine is the culmination of years of research and innovation, where every detail has been meticulously designed to deliver exceptional performance and durability.[Company Name] has earned a commendable reputation in the global plastic extrusion industry for their commitment to product excellence and customer satisfaction. Their comprehensive after-sales service includes technical support, regular maintenance, and spare parts availability, ensuring customers can maximize the longevity and efficiency of their LDPE Extruder Machine.As the global demand for high-quality plastic products continues to rise, [Company Name] remains at the forefront of innovation, empowering manufacturers to meet this demand effectively. The introduction of the LDPE Extruder Machine represents another significant milestone in the company's quest for excellence, setting new benchmarks for performance, reliability, and sustainability in the plastic extrusion industry.About [Company Name]:[Company Name] is a leading manufacturer and supplier of plastic extrusion machinery, with a focus on delivering cutting-edge technology and exceptional product quality. With decades of experience, the company has established itself as a trusted partner for manufacturers worldwide. [Company Name] offers an extensive range of extrusion machinery, including extruders, co-extruders, and ancillary equipment, tailored to meet the diverse requirements of the plastic industry. For more information, please visit [company website].Contact:[Company Name]Address: [Company Address]Phone: [Company Phone Number]Email: [Company Email]Website: [Company Website]

Powerful Grinder Crusher: The Ultimate Tool for Crushing and Grinding

In recent years, there has been a growing demand for efficient and innovative solutions in the field of material handling and recycling. With the increasing pressure to minimize waste and maximize resource utilization, industries are constantly looking for advanced equipment to streamline their operations. Recognizing this need, the company {} has introduced an innovative grinder crusher that is set to revolutionize the way materials are processed and recycled.The grinder crusher, which will be simply referred to as the G-C, is the latest addition to {}'s extensive line of material handling equipment. This powerful machine is designed to effectively grind and crush a variety of materials, including wood, plastics, and construction debris, making it a versatile tool for a wide range of industries.With its robust construction and cutting-edge technology, the G-C is capable of processing large volumes of materials with ease and efficiency. Equipped with high-speed rotary blades, the grinder crusher is able to reduce materials into small, uniform particles, making it easier to handle and transport for further processing. Additionally, the machine's powerful crushing mechanism ensures that materials are thoroughly broken down, maximizing the extraction of valuable resources and minimizing waste.One of the key features of the G-C is its advanced control system, which allows for precision operation and customization to meet specific processing requirements. This level of flexibility makes the machine suitable for various applications, from recycling facilities to manufacturing plants, where different materials may need to be processed in different ways. The intuitive interface also ensures ease of use, making it accessible to operators of all levels of experience.In addition to its exceptional performance, the G-C is also designed with safety and environmental considerations in mind. The machine is equipped with multiple safety features to protect operators and prevent accidents, while its efficient use of energy and minimal emissions make it an environmentally friendly choice for sustainable operations.As part of {}'s commitment to customer satisfaction, the G-C is backed by a comprehensive support and service network. With a team of highly trained technicians and engineers, the company provides installation, maintenance, and training services to ensure that customers can achieve maximum uptime and productivity with their investment in the grinder crusher.The introduction of the G-C is a testament to {}'s dedication to innovation and excellence in the material handling and recycling industry. With its state-of-the-art technology and versatile capabilities, the grinder crusher is poised to set new standards for efficiency and effectiveness in material processing.The feedback from early adopters of the G-C has been overwhelmingly positive, with many users praising its performance and reliability. Industries that have integrated the machine into their operations have reported significant improvements in their material processing efficiency and overall productivity. As word of the G-C's benefits continues to spread, it is expected to gain traction in various sectors, including waste management, construction, and manufacturing.Looking ahead, {} is committed to further refining and enhancing the G-C, as well as developing other innovative solutions to meet the evolving needs of the industry. By leveraging its expertise and resources, the company aims to continue driving progress and sustainability in material handling and recycling, ultimately contributing to a more efficient and responsible use of resources.