High-Quality Pvc Powder Mixing Machine for Efficient Production

By:Admin

In today's fast-paced manufacturing environment, companies are constantly seeking innovative solutions to streamline production processes and enhance efficiency. One such breakthrough is the PVC Powder Mixing Machine, a cutting-edge technology that is revolutionizing the way PVC products are produced. This state-of-the-art machine is designed to significantly improve mixing efficiency and ensure the uniform distribution of PVC powders, making it a game-changer for the industry.

The PVC Powder Mixing Machine, developed by a leading manufacturer in the plastic machinery industry, is engineered to address the challenges and demands of modern production environments. With its advanced features and capabilities, this machine is poised to transform the way PVC products are manufactured, delivering a new level of speed, precision, and consistency.

One of the key advantages of the PVC Powder Mixing Machine is its ability to effectively blend PVC powders with additives and other materials, creating a homogeneous mixture that meets the highest quality standards. This is achieved through a series of innovative mixing processes, including high-speed rotation and controlled temperature settings, which ensure that the PVC powders are thoroughly and uniformly combined.

Furthermore, the machine is equipped with advanced controls and monitoring systems, allowing operators to precisely adjust mixing parameters and monitor performance in real-time. This level of automation not only enhances the accuracy and repeatability of the mixing process but also minimizes the risk of human error, resulting in a more consistent and reliable output.

Additionally, the PVC Powder Mixing Machine is designed with a focus on operational efficiency and ease of maintenance. Its robust construction and well-engineered components are built to withstand the rigors of continuous production, while also minimizing downtime for maintenance and cleaning. This combination of durability and user-friendly design ensures that the machine can deliver long-term performance and reliability, even in the most demanding production environments.

The introduction of the PVC Powder Mixing Machine represents a significant milestone in the evolution of PVC production technology. By leveraging the latest advancements in materials science, automation, and process engineering, this machine has the potential to unlock new levels of productivity and quality for manufacturers across the industry.

Speaking about the significance of this innovation, a spokesperson for the company behind the PVC Powder Mixing Machine commented, "We are proud to introduce this cutting-edge technology to the market, which we believe will have a transformative impact on the production of PVC products. Our commitment to delivering solutions that empower our customers to achieve new levels of performance and efficiency is reflected in the design and capabilities of this machine."

As the demand for PVC products continues to grow across a wide range of industries, the need for advanced manufacturing technologies has never been greater. The PVC Powder Mixing Machine is set to play a pivotal role in meeting this demand, offering manufacturers a powerful tool to optimize their production processes and stay ahead in a competitive market.

In conclusion, the PVC Powder Mixing Machine represents a significant advancement in PVC production technology, offering manufacturers a powerful solution to enhance mixing efficiency and ensure the uniform distribution of PVC powders. With its advanced features, user-friendly design, and potential to drive new levels of productivity and quality, this machine is poised to revolutionize the industry and empower manufacturers to achieve their production goals with greater ease and confidence.

Company News & Blog

Efficient Plastic Bottle Shredding Machine Receives High Praise

Title: Innovative Plastic Bottle Shredding Machine: Revolutionizing Recycling PracticesIntroduction:In a world that is becoming increasingly cognizant of sustainability and environmental responsibility, recycling initiatives have gained significant momentum. To align with the evolving needs of the industry, a pioneering company has recently introduced an advanced Plastic Bottle Shredding Machine. This innovative technology promises to revolutionize recycling practices by efficiently and effectively managing plastic waste. Through its cutting-edge features and sustainable approach, it seeks to mitigate the environmental impact of plastic bottles, promoting a greener future.Company Overview:Founded on the principles of innovation and sustainability, [Company Name] has been at the forefront of technological advancements in waste management since its inception. With a vision to create a positive impact on the environment, the company constantly pushes the boundaries of recycling technologies. By leveraging its team of highly skilled engineers and researchers, [Company Name] consistently develops state-of-the-art machinery that tackles the growing concern of plastic waste.Plastic Bottle Shredding Machine:With an unwavering commitment to addressing the plastic pollution crisis, [Company Name] has recently unveiled their revolutionary Plastic Bottle Shredding Machine. Designed to streamline recycling processes, the machine is capable of shredding plastic bottles into smaller fragments, which can then be used in various recycling processes such as repurposing for new plastic products or converting into fuel.Efficiency and Productivity:One of the key features of the Plastic Bottle Shredding Machine is its exceptional efficiency and productivity. The state-of-the-art technology employed by [Company Name] ensures that the shredding process is quick and thorough. This innovative machine can handle a significant volume of plastic bottles per hour, making it the ideal solution for recycling facilities of all sizes.Sustainability and Environmentally-friendly Approach:[Company Name] places great emphasis on sustainability and environmental responsibility in all their offerings. The Plastic Bottle Shredding Machine is no exception, incorporating several eco-friendly features. It harnesses energy-efficient mechanisms, reducing power consumption and carbon emissions. By effectively shredding plastic bottles into smaller fragments, the machine promotes the recycling loop, allowing the plastic waste to be transformed into new materials or repurposed products, reducing the demand for virgin plastic.Customizable and User-Friendly Design:Understanding the diverse nature of recycling facilities, [Company Name] has developed a customizable design for the Plastic Bottle Shredding Machine. This allows the machine to adapt to the specific requirements of different recycling operations, ensuring seamless integration into existing recycling processes. Additionally, the user-friendly interface makes the machine easy to operate and maintain, requiring minimal training.Benefits for Recycling Facilities:The introduction of the Plastic Bottle Shredding Machine has numerous benefits for recycling facilities. Firstly, it significantly streamlines the recycling process, saving time and reducing costs. Additionally, the shredded plastic fragments serve as high-quality raw material for the manufacturing of new plastic products, thereby reducing reliance on non-renewable resources. Finally, by limiting the accumulation of plastic waste in landfills, the machine contributes to the overall reduction of environmental pollution.Future Prospects:As global consciousness about the plastic crisis continues to rise, the demand for advanced recycling technologies becomes paramount. [Company Name] is optimistic about the future prospects of the Plastic Bottle Shredding Machine. With a commitment to further research and development, the company aims to enhance the machine's functionality, expand its capacity, and explore other innovative recycling solutions to combat plastic pollution effectively.Conclusion:The introduction of the Plastic Bottle Shredding Machine by [Company Name] marks a significant milestone in the field of recycling. Boasting remarkable efficiency, environmental sustainability, and user-friendly design, this innovative machine promises a new era in plastic waste management. Ultimately, it is through groundbreaking technologies like these that our society can move closer to achieving a greener and more sustainable future.

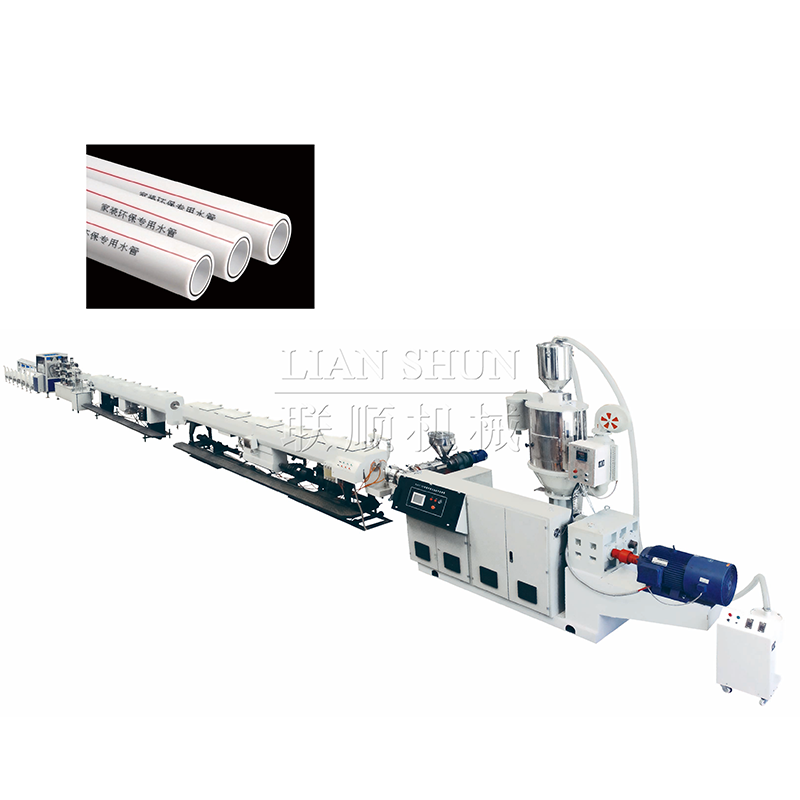

High Quality Pipe Extrusion Machine for PE Material

Pe Pipe Extrusion Machine Revolutionizes the Plastic IndustryThe plastic industry has seen rapid development in recent years, with the demand for high-quality plastic products continuously increasing. In order to meet this demand, modern technology and machinery are essential. One company that is leading the way in this industry is {}.{} has been a key player in the plastic machinery industry for over 20 years, specializing in the design, manufacturing, and sale of plastic extrusion machinery. With a strong commitment to innovation and quality, the company has continuously developed new and advanced products to meet the evolving needs of the market.One of {}'s latest innovations is the Pe Pipe Extrusion Machine, which has revolutionized the plastic industry. This machine is specifically designed for the production of high-quality PE pipes, which are widely used in various applications such as water supply, gas transportation, and agricultural irrigation.The Pe Pipe Extrusion Machine is equipped with the latest technology and features, ensuring optimal performance and efficiency. It is capable of producing pipes with diameters ranging from 16mm to 800mm, meeting the diverse needs of the market. The machine also offers a high degree of automation, allowing for easy operation and minimal human intervention. This not only improves productivity but also reduces labor costs for manufacturers.Moreover, the machine is designed with a focus on energy efficiency, utilizing advanced heating and cooling systems to minimize energy consumption. This not only reduces operational costs for manufacturers but also contributes to environmental sustainability.In addition to its technical capabilities, the Pe Pipe Extrusion Machine is also highly versatile, allowing for the production of various types of PE pipes, including PE80 and PE100. This versatility enables manufacturers to cater to a wide range of applications, further enhancing the machine's value in the market.With its cutting-edge technology and superior performance, the Pe Pipe Extrusion Machine has quickly gained recognition and popularity in the plastic industry. It has set a new benchmark for the production of PE pipes, offering manufacturers a reliable and efficient solution for meeting the increasing demand for high-quality plastic products.In line with its commitment to customer satisfaction and support, {} provides comprehensive services for the Pe Pipe Extrusion Machine, including installation, training, and after-sales support. This ensures that customers can fully leverage the capabilities of the machine and maximize their production efficiency.Furthermore, {}'s dedication to innovation extends beyond its products, with a strong focus on research and development. The company continually invests in research and technology to further enhance the performance and capabilities of its machinery, ensuring that it remains at the forefront of the industry.As the plastic industry continues to evolve, the demand for advanced machinery and technology will only grow stronger. With its Pe Pipe Extrusion Machine and ongoing commitment to innovation, {} is well-positioned to lead the plastic extrusion industry into a new era of efficiency and productivity.In conclusion, the Pe Pipe Extrusion Machine from {} represents a significant advancement in the plastic industry, offering manufacturers a reliable and efficient solution for the production of high-quality PE pipes. With its cutting-edge technology, versatility, and comprehensive support services, the machine has set a new standard for the production of plastic pipes, solidifying {}'s position as a leader in the industry.

Innovative Bottle Recycling Machine: A Step Towards a Sustainable Future

Bottle Recycling Machine Set to Revolutionize Recycling EffortsIn a groundbreaking move towards sustainability, a leading environmental company has recently launched a cutting-edge Bottle Recycling Machine that is poised to revolutionize the way we recycle plastic bottles. This innovative machine is designed to encourage and streamline the recycling process, ultimately reducing the impact of plastic waste on the environment.The Bottle Recycling Machine is the brainchild of {}, a forward-thinking company that is dedicated to developing and implementing sustainable solutions for environmental issues. With a strong emphasis on reducing plastic pollution and promoting a circular economy, {} has been at the forefront of environmental advocacy and innovation for over a decade.The newly developed Bottle Recycling Machine is a testament to the company's commitment to sustainability. Equipped with state-of-the-art technology, the machine is capable of efficiently processing and recycling plastic bottles, making it easier and more convenient for individuals and businesses to participate in recycling efforts. By providing a user-friendly and accessible platform for recycling, {} aims to increase public engagement in environmental conservation and reduce the amount of plastic waste that ends up in landfills and oceans.One of the key features of the Bottle Recycling Machine is its user-friendly interface, which allows individuals to easily deposit their plastic bottles for recycling. The machine is equipped with sensors that can identify and sort different types of plastic, ensuring that each bottle is processed and recycled according to its specific composition. This level of precision not only maximizes the recycling potential of each bottle but also contributes to the overall efficiency and effectiveness of the recycling process.Furthermore, the Bottle Recycling Machine is designed to incentivize recycling through a rewards system. Users who deposit their plastic bottles into the machine are rewarded with points or incentives that can be redeemed for various rewards, such as discounts at participating stores or charitable donations. This innovative approach not only encourages recycling but also fosters a sense of community involvement and responsibility towards the environment.In addition to its environmental benefits, the Bottle Recycling Machine also offers economic advantages for businesses and organizations. By implementing this machine on their premises, companies can demonstrate their commitment to sustainability and environmental stewardship, enhancing their brand image and reputation. Furthermore, the machine can serve as a valuable marketing tool, attracting eco-conscious consumers and enhancing customer loyalty.The launch of the Bottle Recycling Machine reflects {}'s vision of a more sustainable and environmentally conscious future. As a company that is deeply invested in environmental innovation, {} is dedicated to developing and implementing solutions that address the pressing environmental challenges of our time. With the Bottle Recycling Machine, the company is not only addressing the issue of plastic pollution but also empowering individuals and businesses to actively participate in creating a more sustainable world.As the world grapples with the consequences of unchecked plastic consumption and waste, the introduction of the Bottle Recycling Machine represents a significant step towards a more sustainable future. By providing a practical and accessible solution for plastic bottle recycling, {} is empowering individuals and businesses to make a tangible difference in the fight against plastic pollution. With this innovative machine, {} is setting a new standard for environmental sustainability and demonstrating the power of innovation in addressing pressing global challenges.

Discover the Importance of HDPE Recycling for a Sustainable Future

The Contribution of {} to HDPE RecyclingThe problem of plastic pollution has become a global concern in recent years, with increased awareness of the negative impact of plastic waste on the environment. One of the most common types of plastic used in packaging and manufacturing is High-Density Polyethylene (HDPE), which is a versatile and durable material. However, the high demand for HDPE has led to an increase in plastic waste, as recycling rates for HDPE have not kept pace with its production. In this context, the role of companies like {} in promoting and contributing to HDPE recycling becomes even more crucial.{} is a leading company in the plastics industry, with a strong commitment to sustainability and environmental responsibility. The company has been at the forefront of promoting HDPE recycling through its innovative and efficient processes. With a focus on reducing the environmental impact of plastic waste, {} has developed advanced recycling techniques that allow for the efficient reprocessing of HDPE materials.One of the key initiatives undertaken by {} is the development of state-of-the-art recycling facilities that are specifically designed for HDPE materials. These facilities utilize advanced sorting, cleaning, and reprocessing technologies to ensure that the recycled HDPE meets the highest quality standards. By investing in these facilities, {} has been able to significantly increase the volume of HDPE materials that are recycled, thereby reducing the amount of plastic waste that ends up in landfills or in the natural environment.In addition to its recycling facilities, {} has also implemented a comprehensive collection and sorting system for HDPE materials. The company has established partnerships with local communities, municipal authorities, and waste management companies to ensure that HDPE waste is properly collected and sorted for recycling. By engaging in these collaborative efforts, {} has been able to create a closed-loop system for HDPE recycling, where plastic waste is collected, recycled, and then used to produce new HDPE products.Furthermore, {} is actively involved in developing and promoting new technologies and processes for HDPE recycling. The company has invested in research and development to find innovative ways to improve the efficiency and cost-effectiveness of HDPE recycling. This includes the exploration of new methods for separating and processing HDPE materials, as well as the development of new applications for recycled HDPE. Through these efforts, {} is not only contributing to the increase in HDPE recycling rates but also driving the development of a more sustainable and circular economy.The impact of {}'s initiatives in HDPE recycling extends beyond environmental conservation. By promoting and supporting HDPE recycling, the company is also contributing to the reduction of virgin plastic production. This, in turn, helps to conserve natural resources, reduce energy consumption, and minimize the carbon footprint associated with plastic manufacturing. As a result, {} is not only fulfilling its corporate social responsibility but also contributing to the global effort to combat plastic pollution and promote sustainable practices.In conclusion, {}'s commitment to HDPE recycling is a testament to its dedication to environmental stewardship and sustainable business practices. Through its advanced recycling facilities, comprehensive collection and sorting system, and ongoing research and development efforts, {} is making a significant contribution to the promotion of HDPE recycling. As the demand for HDPE continues to grow, the role of companies like {} in advancing HDPE recycling will only become more critical. By setting an example for the industry and driving positive change, {} is helping to pave the way towards a more sustainable and environmentally-friendly future.

Cost of HDPE Pipe Manufacturing Plant: All You Need to Know

In recent news, the HDPE pipe manufacturing plant has announced the cost of establishing a new manufacturing facility. The plant, known for its high-quality HDPE pipes, has provided detailed information on the expenses associated with setting up a new production unit. This information will prove to be valuable for investors and stakeholders who are interested in the company's expansion plans.The HDPE pipe manufacturing plant is a renowned supplier of HDPE pipes that are used in various industries such as water supply, drainage systems, and gas transportation. The high-density polyethylene (HDPE) pipes offered by the company are known for their durability, strength, and resistance to corrosion, making them a popular choice for infrastructure projects around the world.According to the company's introduction, it has been in the business for several decades and has built a strong reputation for delivering top-quality products. The company prides itself on its state-of-the-art manufacturing facilities and its commitment to innovation and sustainability. With a focus on research and development, the company has continuously improved its manufacturing processes and product offerings to meet the evolving needs of its customers.With the growing demand for HDPE pipes in various sectors, the HDPE pipe manufacturing plant has decided to expand its operations by setting up a new manufacturing plant. In a recent announcement, the company disclosed the estimated cost of establishing a new facility, which includes expenses related to land acquisition, construction, machinery, and labor.The cost of setting up a new HDPE pipe manufacturing plant can vary depending on various factors such as the size of the facility, location, and technological requirements. The company has provided a detailed breakdown of the estimated expenses, which will be beneficial for potential investors and partners who are considering collaborating with the company for its expansion project.The cost of land acquisition is a significant factor in establishing a new manufacturing plant. The company has identified potential locations for the new facility and has estimated the expenses associated with acquiring the land. This includes the cost of purchasing the land, obtaining necessary permits and approvals, and preparing the site for construction.Construction expenses are another crucial aspect of setting up the new manufacturing plant. The company has outlined the estimated costs of building the facility, including the construction of production units, warehouses, office space, and utilities. Additionally, the expenses related to infrastructure development, such as roads, drainage systems, and security measures, have also been taken into account.Furthermore, the company has provided detailed information on the estimated cost of machinery and equipment required for the new manufacturing plant. This includes the purchase of specialized machinery for the production of HDPE pipes, as well as the installation and commissioning of technological systems to ensure efficient and high-quality manufacturing processes.Labor costs are also a significant component of the overall expenses. The company has calculated the projected expenses for hiring and training skilled workers, as well as ongoing operational costs related to labor. This includes salaries, benefits, and employee development programs to maintain a competent workforce for the new facility.The announcement of the estimated cost of establishing a new manufacturing plant by the HDPE pipe manufacturing plant demonstrates the company's commitment to transparency and openness in its expansion plans. It provides valuable insights for potential investors and stakeholders who are interested in collaborating with the company for its growth initiatives.With its strong reputation, commitment to quality, and innovative approach, the HDPE pipe manufacturing plant is poised to make a significant impact in the industry with its expansion project. The release of the plant's cost estimates is a positive step towards attracting partnerships and investments to support its growth and further strengthen its position as a leading supplier of HDPE pipes in the global market.

Top Extruder Manufacturers in the Industry

Extruder Manufacturers Establishes Itself as a Leading Player in the IndustryExtruder Manufacturers has been making waves in the industry with their innovative and high-quality extrusion equipment. The company, headquartered in [location], has quickly established itself as a leading player in the market, thanks to its cutting-edge technology and commitment to customer satisfaction. With a focus on continuous improvement and a customer-centric approach, Extruder Manufacturers has become a trusted name in the industry.Established in [year], Extruder Manufacturers has a long-standing reputation for providing top-of-the-line extrusion equipment to a wide range of industries including [industry 1], [industry 2], and [industry 3]. The company's product line includes a variety of extruders designed for different applications, such as plastic extrusion, food extrusion, and rubber extrusion. Extruder Manufacturers has distinguished itself from its competitors through its relentless commitment to product quality and customer service. The company's team of highly skilled engineers and technicians work tirelessly to ensure that every product meets the highest standards of performance and reliability. In addition, Extruder Manufacturers offers comprehensive support and after-sales service to its customers, ensuring that they get the most out of their investment.In recent years, Extruder Manufacturers has invested heavily in research and development, resulting in the introduction of several groundbreaking products that have set new benchmarks in the industry. The company's state-of-the-art manufacturing facilities are equipped with the latest technology, allowing them to stay ahead of the curve and continue to meet the evolving needs of their customers.One of Extruder Manufacturers' key strengths is its ability to customize its products to meet the specific requirements of its clients. Whether it's designing a new extrusion line from scratch or modifying an existing one, the company's team of experts works closely with customers to develop tailored solutions that address their unique challenges.Extruder Manufacturers has also been proactive in adopting sustainable practices in its operations. The company is committed to reducing its environmental footprint by incorporating energy-efficient technologies in its products and processes. By prioritizing sustainability, Extruder Manufacturers is not only contributing to a greener planet but also helping its customers achieve their own sustainability goals.With a growing global footprint, Extruder Manufacturers is continuously expanding its presence in key markets around the world. The company has a strong network of distributors and partners in various countries, allowing it to reach customers from diverse backgrounds and industries. This global reach has helped Extruder Manufacturers build a solid reputation as a reliable and trustworthy partner for extrusion equipment.Looking ahead, Extruder Manufacturers is poised for further growth and success as it continues to innovate and set new industry standards. The company remains committed to its core values of quality, innovation, and customer satisfaction, and is dedicated to delivering superior products and services to its customers. With a customer-centric approach and a focus on sustainability, Extruder Manufacturers is well-positioned to lead the industry and shape the future of extrusion technology.In conclusion, Extruder Manufacturers has firmly established itself as a leading player in the industry, thanks to its relentless commitment to quality, innovation, and customer satisfaction. The company's dedication to excellence and sustainability, combined with its global presence, makes it a preferred choice for customers seeking top-notch extrusion equipment. As Extruder Manufacturers continues to push the boundaries of what's possible in the industry, it is poised to remain at the forefront of extrusion technology for years to come.

Innovative Plastic Recycling Machine Plant Promises Sustainable Solution for Plastic Waste

Plastic pollution is a growing concern for the environment, with millions of tonnes of plastic waste ending up in our landfills and oceans every year. In response to this environmental crisis, the company, a leading provider of innovative solutions for the recycling industry, has recently unveiled a state-of-the-art plastic recycling machine plant that is set to revolutionize the way plastic waste is processed and reused.The new plant is a significant milestone for the company, as it represents a major investment in sustainable technology and underscores their commitment to creating a circular economy for plastics. The plant is equipped with cutting-edge technology that is capable of processing a wide variety of plastic waste, including bottles, packaging, and other single-use plastics, and turning them into high-quality recycled pellets that can be used to make new plastic products.One of the key features of the plant is its advanced sorting and cleaning system, which is able to efficiently separate different types of plastics and remove any contaminants, such as labels, caps, and other non-plastic materials. This ensures that the recycled pellets produced by the plant are of the highest quality and can be used in a wide range of applications, from the production of new packaging materials to the manufacturing of durable plastic products.The new plant also incorporates innovative technology for the recycling of plastic films and flexible packaging, which are notoriously difficult to recycle due to their thin and flexible nature. With the introduction of this new plant, the company aims to address this challenge and significantly increase the recycling rate of these commonly used plastic materials.In addition to its advanced recycling capabilities, the plant is also designed with sustainability in mind. It is equipped with energy-efficient machinery and utilizes processes that minimize water consumption and waste generation. Furthermore, the plant is operated by a team of highly skilled professionals who are trained in the latest best practices for sustainable and environmentally friendly recycling.The introduction of this plastic recycling machine plant is expected to have a positive impact on the environment by reducing the amount of plastic waste that ends up in landfills and oceans. By providing a reliable and efficient solution for recycling plastic waste, the company is contributing to the global effort to combat plastic pollution and create a more sustainable future for the planet.Furthermore, the plant is also expected to create new opportunities for the local community by generating jobs and stimulating economic growth. As the demand for recycled plastics continues to grow, the plant is poised to play a crucial role in meeting this demand and supporting the development of a thriving recycling industry.The company's commitment to sustainability and innovation is further underscored by their ongoing research and development efforts to further improve the efficiency and capabilities of their recycling technology. They are continuously exploring new ways to recycle even more types of plastic waste and are dedicated to staying at the forefront of technological advancements in the recycling industry.With the unveiling of the new plastic recycling machine plant, the company is setting a new standard for sustainable plastic waste management and demonstrating their dedication to making a positive impact on the environment. By investing in cutting-edge recycling technology and embracing a circular economy approach, they are paving the way for a more sustainable and responsible handling of plastic waste. It is clear that their efforts are not only benefiting the environment but also contributing to the creation of a more sustainable future for generations to come.

High-quality Pipe Making Machine for Producing PPRC Pipes

The PPRC pipe making machine is a cutting-edge piece of equipment that is revolutionizing the pipe manufacturing industry. With its advanced technology and innovative features, this machine is capable of producing high-quality PPRC pipes at an unprecedented rate. This groundbreaking machine is the product of extensive research and development, and it is setting a new standard for efficiency and precision in pipe production.The [Company Name] is renowned for its expertise in the field of industrial machinery manufacturing. With a strong focus on innovation and quality, the company has earned a reputation as a leading provider of cutting-edge equipment for a wide range of industries. The company's commitment to excellence is evident in its state-of-the-art manufacturing facilities and its team of highly skilled engineers and technicians. With a dedication to continuous improvement and a focus on customer satisfaction, the [Company Name] is at the forefront of technological advancements in the industrial machinery sector.The PPRC pipe making machine is a prime example of the company's commitment to innovation and quality. With its advanced design and precision engineering, this machine is capable of producing PPRC pipes with exceptional accuracy and consistency. The machine's high-speed production capabilities and efficient operation make it an invaluable asset for pipe manufacturers looking to streamline their production processes and increase output.This cutting-edge machine is equipped with a range of advanced features, including a high-performance extrusion system, precise temperature control, and a sophisticated pipe cutting mechanism. These features work together to ensure that the machine can produce PPRC pipes of the highest quality, with minimal waste and maximum efficiency. Additionally, the machine is designed to be easy to operate and maintain, making it an ideal solution for manufacturers looking to optimize their production processes.The PPRC pipe making machine is also highly versatile, capable of producing a wide range of pipe sizes and specifications. This flexibility makes it an invaluable asset for manufacturers operating in diverse markets and industries, enabling them to meet the specific needs of their customers with ease. Furthermore, the machine's modular design and customizable production settings allow for rapid reconfiguration and adaptation to changing production requirements, providing manufacturers with a high degree of flexibility and agility.In addition to its advanced technological capabilities, the PPRC pipe making machine also prioritizes safety and environmental sustainability. The machine is equipped with comprehensive safety features and protocols to ensure the well-being of operators and the integrity of the production process. Furthermore, the machine is designed to minimize energy consumption and waste generation, making it an environmentally friendly and cost-effective solution for pipe manufacturers.With the introduction of the PPRC pipe making machine, the [Company Name] is once again demonstrating its commitment to driving innovation and progress in the industrial machinery sector. This cutting-edge machine is poised to revolutionize the pipe manufacturing industry, providing manufacturers with a powerful tool for enhancing productivity, quality, and efficiency. As the industry continues to evolve, the [Company Name] remains at the forefront of technological advancements, empowering manufacturers to thrive in an increasingly competitive and dynamic market.In conclusion, the PPRC pipe making machine represents a significant leap forward in pipe manufacturing technology. With its advanced features, high-speed production capabilities, and versatility, this machine is redefining the standards of efficiency and precision in the industry. Backed by the expertise and excellence of the [Company Name], the PPRC pipe making machine is poised to transform the way pipes are produced, setting a new benchmark for quality and innovation in the industrial machinery sector.

Efficient Plastic Drum Crusher for Waste Reduction

Plastic Drum Crusher is a revolutionary machine that has been introduced by a leading waste management company. This innovative product is designed to efficiently crush and compact plastic drums, reducing their volume and making them easier to store and transport for recycling.The Plastic Drum Crusher is an essential tool for companies that generate a large number of plastic drums as part of their daily operations. These drums can take up a significant amount of space and can be difficult to manage, especially when it comes to storage and transportation. With the introduction of this new machine, businesses can now easily crush and compact their plastic drums, significantly reducing the amount of space they occupy.The company behind the Plastic Drum Crusher has a long history of providing innovative waste management solutions to a wide range of industries. They have developed a reputation for delivering high-quality products that are not only effective but also environmentally friendly. With their focus on sustainability and efficiency, they are constantly looking for new ways to help businesses reduce their environmental impact and improve their operations.The Plastic Drum Crusher is the latest addition to the company's extensive range of waste management equipment. It has been designed with the user in mind, featuring a simple and intuitive interface that makes it easy to operate. The machine is also built to last, with a robust construction that ensures it can withstand the rigors of daily use in a busy industrial environment.One of the key features of the Plastic Drum Crusher is its ability to crush plastic drums of varying sizes. This versatility makes it suitable for businesses of all sizes, from small-scale operations to large industrial facilities. The machine can handle drums of different shapes and sizes, making it a versatile and practical solution for a wide range of businesses.In addition to its practical design, the Plastic Drum Crusher also prioritizes safety. It is equipped with a range of safety features to ensure that operators can use it with confidence. These include safety interlocks and emergency stop buttons, as well as guards and covers to protect users from moving parts.The introduction of the Plastic Drum Crusher is set to have a significant impact on the waste management industry. Businesses that invest in this innovative machine will benefit from increased efficiency, reduced waste volumes, and lower transportation costs. In addition, they will also be contributing to a more sustainable and environmentally friendly approach to waste management.The company behind the Plastic Drum Crusher is committed to supporting businesses in their efforts to improve their waste management practices. They offer comprehensive support and training to ensure that customers can get the most out of their investment in the machine. This includes installation, maintenance, and ongoing technical support, as well as advice on best practices for waste management.In conclusion, the introduction of the Plastic Drum Crusher represents a major step forward in the waste management industry. This innovative machine offers businesses an effective and practical solution for managing plastic drums, reducing waste volumes, and improving their environmental impact. With its focus on efficiency, safety, and sustainability, the Plastic Drum Crusher is set to become an essential tool for businesses looking to improve their waste management practices.

High-Quality PVC Pipe Extrusion Machine for Efficient Production

PVC Pipe Extrusion Machine Leads the Industry with Innovation and QualityThe PVC pipe extrusion machine is a vital piece of equipment in the manufacturing of PVC pipes, which are essential components in numerous industries including construction, agriculture, and water supply. The latest advancements in PVC pipe extrusion technology have revolutionized the industry, leading to higher productivity, improved quality, and reduced production costs.One company at the forefront of this innovation is {Company Name}. With a long history of providing top-of-the-line PVC pipe extrusion machines, {Company Name} has established itself as a leader in the field. The company's commitment to research and development has led to the creation of cutting-edge equipment that meets the evolving needs of the industry.The PVC pipe extrusion machine produced by {Company Name} features state-of-the-art technology that ensures precision and efficiency in the extrusion process. The machine is designed to handle a wide range of PVC pipe sizes and specifications, allowing manufacturers to produce pipes that meet the diverse requirements of their customers.One of the key features of {Company Name}'s PVC pipe extrusion machine is its high level of automation, which streamlines the production process and minimizes the need for manual intervention. This results in increased productivity and reduced labor costs, making the machine a valuable investment for PVC pipe manufacturers.In addition to its advanced technology, the PVC pipe extrusion machine from {Company Name} is also known for its exceptional quality and durability. The use of high-quality materials and precision engineering ensures that the machine performs reliably, delivering consistent results with minimal maintenance requirements.Another important aspect of {Company Name}'s PVC pipe extrusion machine is its energy efficiency. The machine is designed to minimize energy consumption, helping manufacturers reduce their operating costs and environmental impact.{Company Name} takes pride in providing comprehensive support to its customers, offering installation, training, and technical assistance to ensure optimal performance of its PVC pipe extrusion machines. The company's team of experienced engineers and technicians are dedicated to helping customers maximize the potential of their equipment.With a strong focus on innovation and customer satisfaction, {Company Name} continues to push the boundaries of PVC pipe extrusion technology. The company's commitment to excellence has earned it a reputation as a trusted partner for PVC pipe manufacturers worldwide.In conclusion, the PVC pipe extrusion machine from {Company Name} represents the latest advancements in technology and quality in the industry. With its innovative features, exceptional performance, and comprehensive support, the machine is a game-changer for PVC pipe manufacturers looking to stay ahead in a competitive market. As the demand for PVC pipes continues to grow, {Company Name} remains at the forefront, providing cutting-edge solutions that meet the evolving needs of the industry.