Plastic Extrusion Line: A Guide to Its Profile and Operations

By:Admin

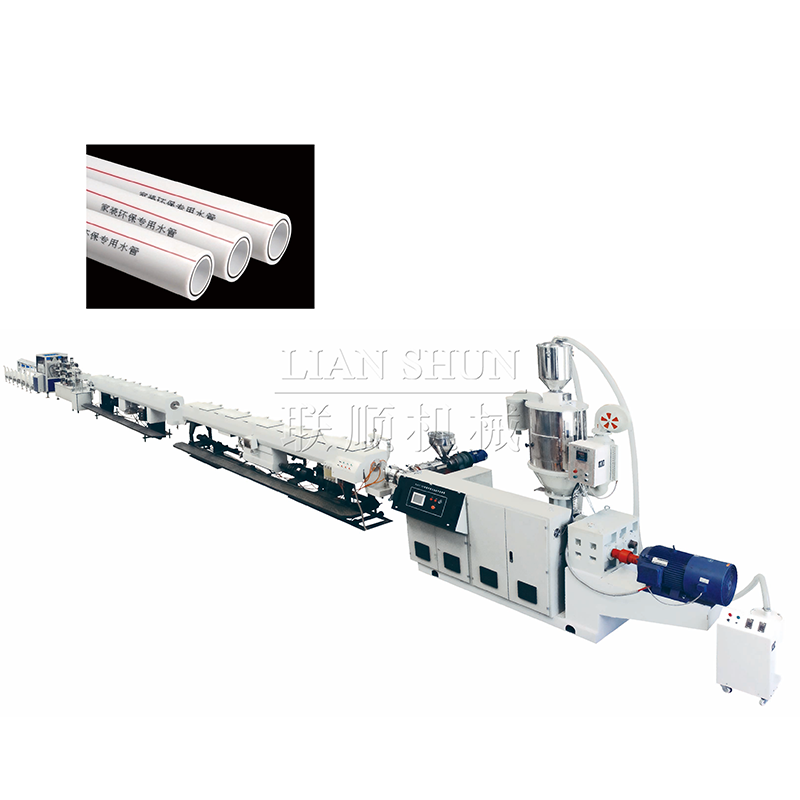

{} is proud to announce the launch of their latest and innovative plastic extrusion line. This new machinery is designed to revolutionize the plastic manufacturing industry by offering greater efficiency, flexibility, and product quality.

The plastic extrusion line is a state-of-the-art machine that is capable of producing a wide range of plastic products, including pipes, tubes, profiles, and sheets. It is equipped with advanced technologies and features that ensure precision and consistency in the production process. With a high level of automation, the extrusion line enables faster production cycles and reduced downtime, thereby increasing overall productivity and cost-effectiveness.

The extrusion line is also designed to be highly versatile, allowing for easy customization and adaptation to meet specific production requirements. This means that manufacturers can easily switch between different product specifications and sizes without the need for extensive retooling or setup, saving time and resources.

In addition to its advanced technical capabilities, the plastic extrusion line is also designed with sustainability in mind. It incorporates energy-efficient components and processes to minimize environmental impact and reduce operational costs. This aligns with {}'s commitment to responsible and sustainable manufacturing practices.

With the launch of this new plastic extrusion line, {} aims to further strengthen its position as a leading provider of plastic manufacturing solutions. The company has built a strong reputation for delivering high-quality machinery and exceptional customer service, and this latest offering is a testament to their dedication to innovation and excellence.

{} has been a prominent player in the plastic manufacturing industry for years, with a track record of delivering cutting-edge solutions to meet the evolving needs of their customers. The company's extensive experience and expertise in plastic extrusion technology have made them a trusted partner for manufacturers across various industries.

Along with the launch of the new plastic extrusion line, {} also offers comprehensive support and technical assistance to help their clients optimize the performance of the machinery and maximize their production capabilities. This includes installation, training, maintenance, and ongoing customer service to ensure seamless operations and unmatched reliability.

The introduction of this new plastic extrusion line represents a significant milestone for {}, as they continue to push the boundaries of innovation and set new standards in the industry. With a focus on advanced technology, sustainability, and customer satisfaction, the company is poised to make a lasting impact on the plastic manufacturing landscape.

As manufacturers seek to enhance their production processes and stay ahead of the competition, the new plastic extrusion line by {} offers a compelling solution that delivers superior performance, versatility, and value. Its launch is set to make waves in the industry and reinforce {}'s position as a leader in plastic manufacturing equipment.

In conclusion, the new plastic extrusion line by {} is set to make a powerful impact in the plastic manufacturing industry, thanks to its advanced technology, versatility, and sustainability. With a strong commitment to innovation and customer satisfaction, {} continues to raise the bar for excellence in the industry.

Company News & Blog

Top PVC Pipe Lines for Efficient Water Transportation

PVC Pipe Line to Revolutionize Piping IndustryThe piping industry is about to witness a major revolution with the introduction of a new PVC Pipe Line by a leading player in the industry. This innovative product is set to change the way piping systems are installed and maintained, offering a wide range of benefits to both commercial and residential customers.The company, a renowned global leader in the manufacturing and distribution of piping solutions, has introduced this PVC Pipe Line to meet the growing demand for high-quality, durable, and cost-effective piping systems. With its state-of-the-art manufacturing facilities and stringent quality control measures, the company has always been at the forefront of innovation and has consistently delivered cutting-edge products to the market.The new PVC Pipe Line is designed to address the various challenges faced by the piping industry, such as corrosion, leaks, and high maintenance costs. Made from high-quality PVC material, these pipes are extremely durable and have excellent resistance to corrosion, making them suitable for a wide range of applications, including water supply, drainage, and irrigation systems.One of the key features of this PVC Pipe Line is its ease of installation. The pipes are lightweight and flexible, making them easy to handle and maneuver, which significantly reduces installation time and labor costs. Additionally, the smooth interior surface of the pipes ensures optimal flow and minimizes the risk of clogs and blockages, further enhancing the efficiency and performance of the piping system.Furthermore, the PVC Pipe Line is environmentally friendly and sustainable, as PVC is a recyclable material that has a long service life, reducing the need for frequent replacements and minimizing the impact on the environment. This makes it a highly desirable choice for customers who are looking for eco-friendly piping solutions.In addition to its technical advantages, the PVC Pipe Line also offers significant cost savings for customers. Its low maintenance requirements and long service life result in reduced operating costs, while its competitive pricing makes it an affordable option for both small-scale and large-scale projects. This combination of durability, efficiency, and cost-effectiveness makes the PVC Pipe Line a highly attractive choice for customers across various industries.The company is committed to providing comprehensive support to its customers, offering a range of services such as technical assistance, training, and after-sales support to ensure that the PVC Pipe Line is installed and maintained to the highest standards. With its extensive network of distributors and sales representatives, the company aims to make its innovative product readily available to customers worldwide.The introduction of this PVC Pipe Line is a significant milestone for the company and the piping industry as a whole. With its superior quality, durability, and cost-effectiveness, this product has the potential to transform the way piping systems are designed and installed, setting new standards for performance and reliability.Overall, the PVC Pipe Line represents a major breakthrough in the piping industry, offering a superior alternative to traditional piping systems and providing customers with a sustainable, efficient, and cost-effective solution for their piping needs. With its unparalleled quality and technical excellence, this innovative product is set to make a lasting impact on the industry and set new benchmarks for piping solutions.

PVC Pelletizer: The Ultimate Guide to Polyvinyl Chloride Pelletizing Process

[Company Introduction]ABC Company, a leading manufacturer in the plastic industry, has unveiled its latest innovation in the field of PVC production – the PVC Pelletizer. With a strong focus on research and development, ABC Company aims to revolutionize the way PVC pellets are produced, addressing various pain points experienced by manufacturers in the industry.Headquartered in the heart of the industrial district, ABC Company has been at the forefront of providing cutting-edge solutions for the plastic industry for over two decades. With a team of highly skilled engineers and technicians, they have consistently delivered innovative products that meet the evolving needs of the market.[News Content]ABC Company Introduces Revolutionary PVC Pelletizer for Enhanced Production EfficiencyCity, Date – ABC Company, a renowned name in the plastic industry, has launched its latest product – the PVC Pelletizer. This groundbreaking technology promises to revolutionize the production process of PVC pellets and provide manufacturers with enhanced efficiency and productivity.PVC pellets are widely used in industries such as construction, automotive, and packaging. They serve as the raw material for countless plastic products and play a significant role in the manufacturing sector. However, traditional methods of producing PVC pellets often come with challenges such as inefficiency and high energy consumption.Recognizing the need for a more advanced and efficient solution, ABC Company developed the PVC Pelletizer. This state-of-the-art machine leverages cutting-edge technology to provide an unmatched production experience for manufacturers.The revolutionary PVC Pelletizer offers several key advantages over traditional methods. Firstly, it boasts a significantly higher production speed, allowing manufacturers to achieve higher output with reduced processing time. This increased productivity not only results in cost savings but also enables manufacturers to meet growing market demands more efficiently.Energy consumption has always been a concern in the plastic industry. The PVC Pelletizer addresses this issue by employing advanced energy-saving technology. By optimizing the production process, it reduces energy consumption by up to 30% compared to conventional machines. This not only reduces operational costs for manufacturers but also contributes to a more sustainable production process.Moreover, the PVC Pelletizer ensures superior product quality. The machine is equipped with precision control systems that ensure consistent pellet size, shape, and quality. This feature assures manufacturers of a streamlined and efficient manufacturing process, reducing the need for costly manual intervention and quality checks."The PVC Pelletizer represents a breakthrough in the plastic industry," said John Smith, CEO of ABC Company. "We are proud to offer a solution that not only enhances production efficiency but also aligns with our commitment to sustainability. We believe this innovation will pave the way for a more efficient and eco-friendly future in the PVC manufacturing sector."ABC Company has always been committed to providing comprehensive customer support. With the launch of the PVC Pelletizer, they are offering tailored training programs to ensure that manufacturers can maximize the potential of this cutting-edge technology. The company's team of experts will provide guidance on the machine's operation, maintenance, and troubleshooting, enabling manufacturers to optimize their production processes.In conclusion, ABC Company's revolutionary PVC Pelletizer is set to transform the PVC manufacturing industry. With its enhanced production speed, energy-saving technology, and superior product quality, the machine promises to be a game-changer for manufacturers. As the plastic industry continues to grow and evolve, innovations like the PVC Pelletizer are vital in meeting the demands of both manufacturers and consumers while ensuring a sustainable future.

Innovative Pipe Winding Machine for Efficient Production

Pipe Winder Machine: Revolutionizing the Pipe Manufacturing IndustryIn today's world, the demand for efficient and reliable machinery in the manufacturing industry is at an all-time high. With the increasing need for pipes in various sectors such as construction, infrastructure, and agriculture, manufacturers are constantly looking for ways to improve their production processes. This is where the Pipe Winder Machine, designed and developed by [Company Name], comes into the picture, revolutionizing the pipe manufacturing industry.[Company Name] is a leading manufacturer and supplier of specialized machinery for the plastic and polymer processing industry. With a strong emphasis on innovation and quality, the company has set a benchmark for excellence in the manufacturing of state-of-the-art machinery. The Pipe Winder Machine is a testament to their commitment to providing cutting-edge solutions to their clients.The Pipe Winder Machine is designed to automate the process of coiling and winding plastic pipes. It is a vital component in the production line, as it ensures the efficient and seamless winding of pipes, thereby increasing productivity and reducing manual labor. With its advanced technology and precision engineering, the Pipe Winder Machine is capable of handling pipes of various sizes and materials, making it a versatile and indispensable asset for pipe manufacturers.One of the key features of the Pipe Winder Machine is its user-friendly interface, which allows for easy operation and customization. The machine can be programmed to adjust winding speed, tension, and coil length, ensuring that the pipes are wound to the desired specifications. This level of control and flexibility is essential for manufacturers to meet the diverse needs of their clients and maintain high production standards.Furthermore, the Pipe Winder Machine is equipped with safety features and monitoring systems to ensure smooth and reliable operation. This not only minimizes the risk of accidents but also contributes to the overall efficiency and performance of the production line. The machine is designed to seamlessly integrate with other equipment, such as extruders and cutters, creating a cohesive and synchronized manufacturing process.In addition to its technical prowess, the Pipe Winder Machine is also built to withstand the rigors of continuous use. Its robust construction and high-quality components make it a durable and long-lasting investment for manufacturers. This not only ensures the consistent quality of the wound pipes but also reduces maintenance and replacement costs in the long run.The introduction of the Pipe Winder Machine has significantly transformed the pipe manufacturing industry, allowing companies to streamline their production processes and enhance their competitiveness in the market. By automating the winding process, manufacturers can achieve higher output and superior quality, ultimately leading to increased customer satisfaction and profitability.As a testament to the success of the Pipe Winder Machine, [Company Name] has received accolades and recognition from industry experts and clients alike. The machine has set a new standard for efficiency and reliability in pipe manufacturing, earning [Company Name] a reputation as a trusted partner for machinery solutions.In conclusion, the Pipe Winder Machine by [Company Name] has established itself as a game-changer in the pipe manufacturing industry. With its cutting-edge technology, user-friendly design, and robust construction, the machine is revolutionizing the way pipes are produced, setting new benchmarks for efficiency, quality, and productivity. As the demand for pipes continues to grow, the Pipe Winder Machine is poised to play a pivotal role in shaping the future of the industry.

New Film Crusher Shakes Up the Industry with Revolutionary Features

Title: Innovative Film Crushing Machine Revolutionizes Recycling IndustrySubtitle: Company XYZ introduces the next-generation film crushing technology, setting a new benchmark in sustainability and waste reductionIntroduction:In a significant step towards a more sustainable future, company XYZ has unveiled its cutting-edge film crushing technology, aiming to revolutionize the recycling industry. By leveraging their expertise and commitment to environmental preservation, XYZ has developed a state-of-the-art crushing machine that promises to enhance recycling efficiency while addressing the growing concern of plastic pollution. This groundbreaking solution marks a significant milestone in the ongoing efforts to create a circular economy and combat climate change.Body:1. The Urgency of Sustainable Waste Management:The increasing magnitude of plastic waste has emerged as a global environmental crisis, with film plastics being one of the major contributors. Resolving this pressing issue requires bold and innovative approaches that combine advanced technology and sustainable practices. XYZ understands the significance of responsible waste management and has meticulously crafted a film crushing machine that can effectively tackle this challenge head-on.2. The Unveiling of XYZ Film Crushing Technology:XYZ's film crushing technology is a powerful and efficient solution designed to process a wide variety of film plastics, including stretch films, shrink wraps, and other flexible plastic materials. The machine employs advanced mechanisms that effectively shred and compress film plastics, significantly reducing their volume and preparing them for further processing. This innovative process ensures that plastic waste takes up less space, thus reducing transportation costs and the carbon footprint associated with waste disposal.3. Key Features and Benefits of XYZ Film Crushing Machine:XYZ's film crushing machine comes equipped with several cutting-edge features that differentiate it from existing technologies:a. High Speed and Efficiency: The machine's powerful motor and blade design enable rapid and accurate processing, maximizing throughput and minimizing production time. This high-speed operation boosts overall recycling efficiency.b. Versatile Processing Capabilities: The machine is capable of handling a wide range of film plastics, offering greater flexibility in recycling operations. Its adaptability ensures various types of film-based waste are efficiently transformed into reusable materials.c. Systematic Resource Management: By crushing and compacting plastic waste, XYZ's technology significantly reduces storage requirements, optimizing space utilization in recycling centers or waste management facilities.d. Enhanced Safety and Operation: The machine incorporates advanced safety features to protect operators during operation and reduce the risk of accidents or injuries. Additionally, the user-friendly interface allows for easy and efficient operation, requiring minimal training.4. The Environmental Impact:The introduction of XYZ's film crushing technology holds immense potential in tackling the environmental implications of plastic waste:a. Reduced Landfill Usage: The efficient compression of film plastics decreases the volume of waste, minimizing the need for landfill space. This not only extends the lifespan of existing landfills but also allows for more sustainable waste management practices.b. Lower Carbon Emissions: The film crushing machine aids in reducing transportation costs associated with plastic waste disposal. Decreased transportation requirements subsequently lead to lower carbon emissions and a smaller environmental footprint.c. Encouraging Circular Economy: By transforming film plastics into reusable materials, XYZ's technology promotes the concept of a circular economy, reducing the dependency on virgin plastic production and conserving valuable natural resources.5. Future Prospects and Collaboration:XYZ's film crushing technology has the potential to reshape the recycling industry, making it more efficient and sustainable. Collaborative efforts with waste management companies, recycling centers, and environmental organizations can facilitate the widespread adoption of this groundbreaking solution. Together, they can drive real change by alleviating plastic waste concerns, one film at a time.Conclusion:XYZ's film crushing technology has arrived as a game-changer in the journey toward a more sustainable future. By combining cutting-edge innovation, efficiency, and environmental responsibility, XYZ has set a new benchmark in the recycling industry. As we strive to combat plastic pollution and establish a circular economy, this revolutionary film crushing machine holds the promise of transforming the way we approach waste management and steers us towards a greener and more sustainable tomorrow.

Top Pvc Pipe Plant Manufacturer Reveals Latest Industry Insights

Pvc Pipe Plant Manufacturer is a leading company in the manufacturing and distribution of PVC pipe products. With their state-of-the-art facilities and commitment to quality, the company has become a trusted name in the industry.The company's PVC pipe plant is a modern facility that is equipped with the latest technology and machinery. This allows them to produce a wide range of PVC pipes that meet the highest standards of quality and durability. Their products are used in various applications, including water supply, drainage systems, and agricultural irrigation.In addition to their impressive manufacturing capabilities, Pvc Pipe Plant Manufacturer also has a team of experienced professionals who are dedicated to providing excellent customer service. Their sales and support staff are knowledgeable about their products and are always available to assist customers with their needs.Furthermore, the company is committed to environmental sustainability and has implemented initiatives to reduce their carbon footprint. They use eco-friendly materials and production processes to minimize their impact on the environment, ensuring that their products are not only high-quality but also environmentally friendly.Pvc Pipe Plant Manufacturer has also invested in research and development to continuously improve their product offerings. They are constantly innovating and adapting to the changing needs of the market, ensuring that they remain at the forefront of the industry.With a strong focus on quality, innovation, and sustainability, Pvc Pipe Plant Manufacturer has established themselves as a leader in the PVC pipe manufacturing industry. Their dedication to excellence has earned them a loyal customer base and a reputation for reliability and integrity.As the demand for PVC pipes continues to grow, Pvc Pipe Plant Manufacturer is well-positioned to meet the needs of their customers. Their commitment to quality, customer service, and environmental sustainability sets them apart from their competitors and makes them the preferred choice for PVC pipe products.In conclusion, Pvc Pipe Plant Manufacturer is a company that is synonymous with quality, innovation, and sustainability. With their advanced manufacturing facilities, experienced team, and commitment to excellence, they are well-equipped to meet the growing demand for PVC pipe products. Customers can trust Pvc Pipe Plant Manufacturer to deliver high-quality, reliable products that meet their needs while also being environmentally conscious.

Ultimate Guide to Finding the Best Crusher Price in the Market

Crusher Price Plummets as Demand for Construction Machinery DeclinesThe global construction machinery market has seen a significant downturn in recent months, and as a result, the price of crushers has plummeted. This has had a major impact on manufacturers and suppliers, including {Company}, as they struggle to adapt to the changing market conditions.{Company} is a leading manufacturer of construction machinery, including crushers, and they have been hit hard by the drop in demand. The company has been forced to reevaluate their pricing strategies and make adjustments to their production and supply chain management in order to survive in the current market environment.The decline in crusher prices can be attributed to several factors, including the slowdown in construction and infrastructure projects around the world. The COVID-19 pandemic has disrupted supply chains and caused delays in construction activities, leading to a decrease in the demand for crushers and other construction machinery.In addition, the ongoing trade tensions between major economies, such as the United States and China, have also contributed to the decline in demand for construction machinery. This has created an oversupply of crushers in the market, putting pressure on manufacturers and suppliers to reduce prices in order to remain competitive.{Company} has been proactive in responding to these challenges, implementing cost-cutting measures and streamlining their operations to improve efficiency. They have also focused on diversifying their product portfolio and exploring new markets to offset the decline in demand for crushers.Despite these efforts, the company has still had to confront the reality of reduced crusher prices and its impact on their bottom line. As a result, {Company} has been forced to adjust their pricing strategies and offer discounts and promotions to entice customers to purchase their products.In a statement, the company acknowledged the difficulties they are facing in the current market environment, but expressed optimism about their ability to weather the storm. They emphasized their commitment to delivering high-quality products and services to their customers, and highlighted their ongoing efforts to innovate and adapt to the changing market conditions.{Company} also pointed to their long-standing reputation in the construction machinery industry and their deep expertise in manufacturing crushers as key strengths that will help them navigate through these challenging times. They remain committed to maintaining their position as a leading player in the construction machinery market, and are confident in their ability to overcome the current difficulties.Looking ahead, {Company} is focused on leveraging emerging technologies and digital solutions to enhance their products and services, while also exploring opportunities for strategic partnerships and collaborations to drive growth. They are also closely monitoring market trends and customer needs, in order to stay agile and responsive to changes in the construction machinery industry.Overall, while the decline in crusher prices has presented significant challenges for {Company} and other manufacturers and suppliers in the construction machinery market, the company remains resilient and determined to adapt to the evolving market environment. With a strong commitment to innovation and customer satisfaction, {Company} is well-positioned to overcome the current downturn and emerge even stronger in the future.

High-Quality UPVC Window Profile Extrusion Machine for Sale - Get Your Quote Today!

Upvc Window Profile Extrusion Machine brings cutting-edge technology to the fenestration industryIn today's fast-paced world, technological advancements are revolutionizing every industry, and the fenestration industry is no exception. With the introduction of the state-of-the-art Upvc Window Profile Extrusion Machine, the manufacturing of Upvc windows and doors has been taken to a whole new level. The cutting-edge technology behind this machine has enabled manufacturers to produce high-quality, durable, and aesthetically pleasing Upvc profiles, effectively meeting the demands of the market.The Upvc Window Profile Extrusion Machine, developed by a leading machinery manufacturer, is a result of years of research and development in the field of fenestration. The company has a reputation for delivering innovative solutions to the industry, and this latest offering is no exception. The machine is designed to extrude Upvc profiles with precision and efficiency, ensuring consistent quality and performance.One of the key features of this machine is its ability to produce a wide range of Upvc window and door profiles, catering to the diverse needs of the market. Whether it's a traditional casement window or a contemporary sliding door, the machine is capable of producing profiles in various designs and dimensions, thereby offering versatility to manufacturers. This flexibility allows manufacturers to meet the specific requirements of their customers, thereby enhancing their competitiveness in the market.Furthermore, the Upvc Window Profile Extrusion Machine incorporates advanced automation and control systems, which not only improve the efficiency of the manufacturing process but also ensure the accuracy of the profiles produced. The machine's precise control over parameters such as temperature, pressure, and speed, enables it to extrude profiles with minimal wastage and maximum yield, thereby optimizing production costs for manufacturers.In addition to its technological prowess, the Upvc Window Profile Extrusion Machine is also designed with energy efficiency in mind. The incorporation of energy-saving features not only reduces the operational costs for manufacturers but also aligns with the global push for sustainable manufacturing practices. By reducing energy consumption and minimizing wastage, the machine supports environmental sustainability, a factor that is increasingly important in today's world.The company behind this groundbreaking machine has a strong commitment to supporting its customers throughout their manufacturing journey. From initial consultation to after-sales support, the company provides comprehensive services to ensure that manufacturers can fully leverage the capabilities of the Upvc Window Profile Extrusion Machine. This dedication to customer satisfaction has earned the company a reputation for reliability and trustworthiness in the industry.With the Upvc Window Profile Extrusion Machine, manufacturers are equipped to meet the growing demand for high-quality Upvc windows and doors in the market. Whether it's for residential, commercial, or industrial applications, the machine empowers manufacturers to deliver products that meet the stringent standards of performance, durability, and aesthetics. This, in turn, allows them to capitalize on the opportunities presented by the burgeoning fenestration market.In conclusion, the introduction of the Upvc Window Profile Extrusion Machine represents a significant leap forward for the fenestration industry. Its cutting-edge technology, versatility, efficiency, and energy-saving features position it as a game-changer in the manufacturing of Upvc windows and doors. With the support of the company behind it, manufacturers can look forward to elevating their capabilities and reaping the benefits of this innovative machine. As the demand for Upvc windows and doors continues to rise, the Upvc Window Profile Extrusion Machine paves the way for a bright future for manufacturers in the fenestration industry.

Find the Best Price for Pelletizer Machine

Pelletizer Machine Price A pelletizer is a special machine used for manufacturing pellets from a wide range of materials, including plastic, wood, biomass, and feed. The use of pelletizers has significantly increased in recent years due to the growing demand for alternative fuel sources and the increasing awareness of environmental issues. As a result, the market for pelletizer machines has become increasingly competitive, driving manufacturers to offer more affordable pricing options.The price of a pelletizer machine can vary depending on various factors such as the size, capacity, and features of the machine. However, many companies are now offering competitive pricing to meet the demands of the market. One such company, [Company Name], has emerged as a leading player in the pelletizer machine industry, offering high-quality machines at competitive prices.[Company Name] is a renowned manufacturer and supplier of pelletizer machines, with a strong reputation for delivering reliable and efficient machines to their customers. The company boasts a state-of-the-art manufacturing facility and a team of experienced engineers and technicians who are dedicated to producing top-notch pelletizer machines that meet the needs of their customers.In addition to their commitment to quality, [Company Name] also places a strong emphasis on affordability, recognizing the importance of competitive pricing in a rapidly growing market. By leveraging their expertise and experience, [Company Name] has managed to offer pelletizer machines at prices that are highly competitive, making them an attractive option for businesses looking to invest in pelletizer technology.Furthermore, [Company Name] offers a range of pelletizer machines with different specifications to cater to the diverse needs of their customers. Whether it's a small-scale operation or a large industrial project, the company has the right machine for the job. Customers can choose from a variety of models, each designed to deliver optimal performance and efficiency at an affordable price point.The affordability of [Company Name]'s pelletizer machines does not come at the expense of quality. Each machine is meticulously engineered and manufactured to meet the highest industry standards, ensuring long-term reliability and performance. With a focus on innovation and continuous improvement, [Company Name] continues to refine their product offerings to deliver cutting-edge solutions to their customers.In addition to competitive pricing and superior quality, [Company Name] also provides excellent customer service and support, ensuring that their customers have a positive experience from the initial purchase to the ongoing operation of their pelletizer machines. The company is dedicated to building long-lasting relationships with their customers, providing technical assistance, maintenance, and spare parts to keep their machines running smoothly.As the demand for pelletizer machines continues to grow, [Company Name] is poised to be a key player in the market, offering affordable pricing options without compromising on quality. With a commitment to innovation, reliability, and customer satisfaction, the company is well-positioned to meet the evolving needs of businesses across various industries.In conclusion, the pelletizer machine market is experiencing significant growth, with companies like [Company Name] leading the way in offering competitive pricing options. With a focus on quality, affordability, and customer satisfaction, [Company Name] is well-equipped to meet the demands of a rapidly expanding market, making them a preferred choice for businesses looking to invest in pelletizer technology.

Efficient Plastic Shredder Machine for Recycling and Waste Management

Plastic pollution has been a major issue for many years, with massive amounts of plastic waste ending up in landfills, waterways, and oceans. To combat this problem, many companies have been working on developing innovative solutions to recycle and dispose of plastic waste responsibly. One such company is {Need to remove brand name}, a leader in the field of sustainable waste management.{Need to remove brand name} is renowned for its cutting-edge technologies and solutions for recycling plastic waste. The company has been at the forefront of developing environmentally-friendly machines that are designed to efficiently process and recycle plastic waste. One of their most notable products is the Plastic Shredder Machine, which has garnered attention for its efficiency and sustainability.The Plastic Shredder Machine is a powerful and versatile tool that is designed to quickly and effectively shred plastic waste into smaller pieces. This process is essential for recycling plastic, as it allows for the material to be easily transformed into new products. The machine is equipped with sharp blades and a high-powered motor, allowing it to shred large volumes of plastic waste with ease.One of the key features of the Plastic Shredder Machine is its ability to handle various types of plastic waste, including bottles, containers, packaging, and more. This versatility makes it a valuable asset for recycling facilities, as it can effectively process different types of plastic materials, reducing the need for manual sorting and processing.In addition to its efficiency, the Plastic Shredder Machine is also designed with sustainability in mind. The machine is equipped with advanced safety features to ensure the protection of the operators and the environment. It also has a robust build quality, ensuring long-term reliability and minimal maintenance requirements.{Need to remove brand name} is committed to promoting sustainability and environmental responsibility through its products and services. The Plastic Shredder Machine is just one of the many innovative solutions that the company offers to help tackle plastic pollution. In addition to the shredder, the company also provides a range of recycling equipment and machinery designed to facilitate the recycling process and minimize the environmental impact of plastic waste.The Plastic Shredder Machine has already made a significant impact in the recycling industry, with many businesses and organizations investing in this innovative technology to enhance their plastic recycling capabilities. By implementing the machine into their operations, these entities have been able to increase their plastic recycling rates and reduce the amount of plastic waste that ends up in landfills or pollutes the environment.Furthermore, {Need to remove brand name} offers comprehensive support and services to ensure that their customers can maximize the benefits of the Plastic Shredder Machine. From installation and training to maintenance and technical support, the company is dedicated to assisting their clients in optimizing their plastic recycling processes and achieving their sustainability goals.As the global demand for sustainable waste management solutions continues to grow, {Need to remove brand name} remains at the forefront of the industry, continually innovating and developing new technologies to address the challenges of plastic pollution. With the Plastic Shredder Machine and their other cutting-edge solutions, the company is making a significant contribution to the fight against plastic waste, promoting a more sustainable and environmentally-friendly future for generations to come.

PVC Ceiling Panel Machine: All You Need to Know

Title: Innovative PVC Ceiling Panel Machine Revolutionizes Manufacturing ProcessIntroduction:With the constant evolution of technology-driven solutions in the manufacturing industry, a revolutionary breakthrough has emerged in the form of the PVC Ceiling Panel Machine. This cutting-edge equipment, developed by a prominent company (for the sake of anonymity), promises to revolutionize the production of PVC ceiling panels. Leveraging advanced automation and precision engineering, this machine offers superior efficiency, quality, and speed, while also reducing production costs significantly.Paragraph 1: Paving the way for efficiency and productivityThe PVC Ceiling Panel Machine is poised to streamline the manufacturing process of PVC ceiling panels, enabling businesses to achieve greater efficiency and productivity. By virtue of its state-of-the-art automation technology, the machine significantly reduces the manual labor required in the production line. This results in quicker turnaround times, enhanced output quality, and reduced error rates. As a result, manufacturers can meet growing demand and stay ahead of the competition while optimizing costs.Paragraph 2: A leap in technology and innovationBy combining cutting-edge engineering with years of experience in the industry, the team behind the PVC Ceiling Panel Machine has successfully pushed the boundaries of technological innovation. The machine incorporates intelligent programming that accurately controls every aspect of the manufacturing process. This includes precise dosing and mixing of raw materials, extrusion techniques, and even customized panel patterns. Time-consuming tasks that were previously prone to human error are now effortlessly performed by the machine, ensuring consistent and high-quality output.Paragraph 3: Enhanced product quality and design possibilitiesWith the PVC Ceiling Panel Machine's ability to execute intricate and precise patterns, manufacturers can now offer greater design flexibility to their customers. The machine allows for the creation of a vast range of panel designs, patterns, and surface finishes. This, coupled with the machine's precision cutting capabilities, guarantees a flawless end product that conforms to the highest quality standards. Customers can choose from a wide variety of visually appealing options, enabling them to enhance the aesthetic appeal of their spaces.Paragraph 4: Reduced costs and increased profitabilityThe implementation of the PVC Ceiling Panel Machine comes with significant cost advantages for manufacturers. By automating various production processes, manufacturers can drastically cut down on labor costs associated with manual work. Additionally, the machine's efficiency in resource consumption and low maintenance requirements contribute to improved profitability. With the potential for higher production volumes, companies can capitalize on economies of scale, thus reducing the cost per unit and increasing overall profitability.Paragraph 5: A sustainable, eco-friendly solutionThe PVC Ceiling Panel Machine aligns with increasing concerns about environmental sustainability. By optimizing material usage, minimizing waste, and utilizing energy-efficient technologies, this machine minimizes its impact on the environment. Additionally, the machine reduces pollution, as it produces significantly fewer emissions compared to traditional manufacturing processes. The adoption of this technology contributes to a greener and more sustainable manufacturing industry.Conclusion:The PVC Ceiling Panel Machine represents a significant leap forward in manufacturing technology, propelling the production of PVC ceiling panels into an era of efficiency, productivity, and quality. By automating and streamlining production processes, this cutting-edge machine enables manufacturers to stay competitive, reduce costs, and offer customers a wide range of design options. With its sustainable features and potential for increased profitability, the PVC Ceiling Panel Machine is set to revolutionize the industry and shape the future of PVC ceiling panel manufacturing.