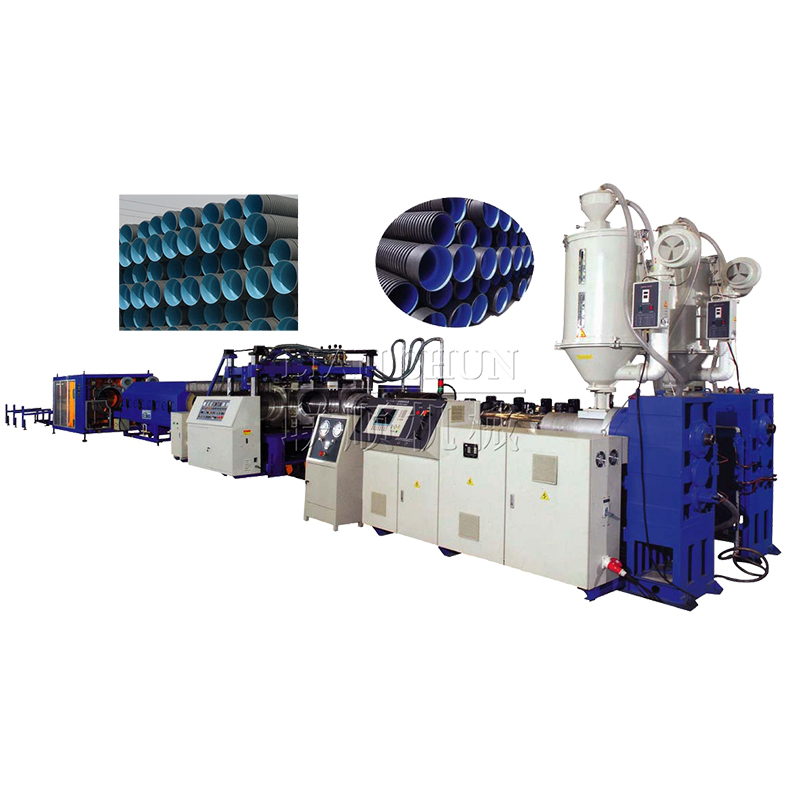

High-Quality PVC Pipe Extrusion Line for Efficient Production

By:Admin

In the competitive world of manufacturing, it's always a challenge to find the perfect balance between quality and efficiency. However, [Company Name]'s latest PVC Pipe Extrusion Line has successfully achieved this delicate balance, setting a new standard in the industry.

The PVC Pipe Extrusion Line is a state-of-the-art manufacturing system designed to produce high-quality PVC pipes with maximum efficiency. It is equipped with advanced technology and precision engineering, allowing for seamless production and consistent product quality.

[Company Name] has always been at the forefront of innovation, and this new PVC Pipe Extrusion Line is a testament to their commitment to excellence. With a focus on research and development, the company has built a reputation for delivering cutting-edge solutions to meet the ever-evolving needs of the industry.

The PVC Pipe Extrusion Line is a comprehensive system that covers all aspects of the pipe manufacturing process. From raw material handling to final product inspection, every step is meticulously optimized for performance and quality. The line is capable of producing a wide range of PVC pipes, from small diameter tubes to large diameter pipes, catering to diverse market demands.

One of the key features of the PVC Pipe Extrusion Line is its exceptional efficiency. Thanks to its innovative design and advanced automation, the line can achieve high production rates while minimizing waste and downtime. This not only improves the overall productivity of the manufacturing process but also reduces operating costs, making it a viable investment for businesses of all sizes.

In addition to efficiency, the PVC Pipe Extrusion Line also upholds the highest standards of product quality. Each pipe produced by the line undergoes rigorous quality control measures to ensure uniformity in dimensions, strength, and appearance. This is essential for meeting industry regulations and satisfying customer expectations.

[Company Name] takes pride in providing comprehensive services to accompany the PVC Pipe Extrusion Line. From installation and commissioning to training and after-sales support, the company offers a complete package to help customers integrate the line seamlessly into their operations.

The PVC Pipe Extrusion Line is not only a product of advanced technology but also a reflection of [Company Name]'s dedication to sustainable manufacturing practices. The line is designed to optimize energy consumption and minimize environmental impact, aligning with the company's commitment to eco-friendly solutions.

The release of the PVC Pipe Extrusion Line has garnered positive feedback from industry professionals and customers alike. Many have praised the line for its exceptional performance, reliability, and versatility, making it a popular choice in the market.

As a company with a global presence, [Company Name] aims to introduce the PVC Pipe Extrusion Line to a wide range of industries, including construction, infrastructure, agriculture, and more. With its ability to produce high-quality PVC pipes efficiently, the line is poised to make a significant impact on the market.

In conclusion, the introduction of the PVC Pipe Extrusion Line marks a significant milestone for [Company Name] and the industry as a whole. With its unparalleled combination of quality and efficiency, the line sets a new benchmark for PVC pipe manufacturing, reaffirming the company's position as a leader in innovative solutions. As the demand for high-quality PVC pipes continues to grow, the PVC Pipe Extrusion Line is poised to play a pivotal role in meeting this need and shaping the future of the industry.

Company News & Blog

New Film Crusher Shakes Up the Industry with Revolutionary Features

Title: Innovative Film Crushing Machine Revolutionizes Recycling IndustrySubtitle: Company XYZ introduces the next-generation film crushing technology, setting a new benchmark in sustainability and waste reductionIntroduction:In a significant step towards a more sustainable future, company XYZ has unveiled its cutting-edge film crushing technology, aiming to revolutionize the recycling industry. By leveraging their expertise and commitment to environmental preservation, XYZ has developed a state-of-the-art crushing machine that promises to enhance recycling efficiency while addressing the growing concern of plastic pollution. This groundbreaking solution marks a significant milestone in the ongoing efforts to create a circular economy and combat climate change.Body:1. The Urgency of Sustainable Waste Management:The increasing magnitude of plastic waste has emerged as a global environmental crisis, with film plastics being one of the major contributors. Resolving this pressing issue requires bold and innovative approaches that combine advanced technology and sustainable practices. XYZ understands the significance of responsible waste management and has meticulously crafted a film crushing machine that can effectively tackle this challenge head-on.2. The Unveiling of XYZ Film Crushing Technology:XYZ's film crushing technology is a powerful and efficient solution designed to process a wide variety of film plastics, including stretch films, shrink wraps, and other flexible plastic materials. The machine employs advanced mechanisms that effectively shred and compress film plastics, significantly reducing their volume and preparing them for further processing. This innovative process ensures that plastic waste takes up less space, thus reducing transportation costs and the carbon footprint associated with waste disposal.3. Key Features and Benefits of XYZ Film Crushing Machine:XYZ's film crushing machine comes equipped with several cutting-edge features that differentiate it from existing technologies:a. High Speed and Efficiency: The machine's powerful motor and blade design enable rapid and accurate processing, maximizing throughput and minimizing production time. This high-speed operation boosts overall recycling efficiency.b. Versatile Processing Capabilities: The machine is capable of handling a wide range of film plastics, offering greater flexibility in recycling operations. Its adaptability ensures various types of film-based waste are efficiently transformed into reusable materials.c. Systematic Resource Management: By crushing and compacting plastic waste, XYZ's technology significantly reduces storage requirements, optimizing space utilization in recycling centers or waste management facilities.d. Enhanced Safety and Operation: The machine incorporates advanced safety features to protect operators during operation and reduce the risk of accidents or injuries. Additionally, the user-friendly interface allows for easy and efficient operation, requiring minimal training.4. The Environmental Impact:The introduction of XYZ's film crushing technology holds immense potential in tackling the environmental implications of plastic waste:a. Reduced Landfill Usage: The efficient compression of film plastics decreases the volume of waste, minimizing the need for landfill space. This not only extends the lifespan of existing landfills but also allows for more sustainable waste management practices.b. Lower Carbon Emissions: The film crushing machine aids in reducing transportation costs associated with plastic waste disposal. Decreased transportation requirements subsequently lead to lower carbon emissions and a smaller environmental footprint.c. Encouraging Circular Economy: By transforming film plastics into reusable materials, XYZ's technology promotes the concept of a circular economy, reducing the dependency on virgin plastic production and conserving valuable natural resources.5. Future Prospects and Collaboration:XYZ's film crushing technology has the potential to reshape the recycling industry, making it more efficient and sustainable. Collaborative efforts with waste management companies, recycling centers, and environmental organizations can facilitate the widespread adoption of this groundbreaking solution. Together, they can drive real change by alleviating plastic waste concerns, one film at a time.Conclusion:XYZ's film crushing technology has arrived as a game-changer in the journey toward a more sustainable future. By combining cutting-edge innovation, efficiency, and environmental responsibility, XYZ has set a new benchmark in the recycling industry. As we strive to combat plastic pollution and establish a circular economy, this revolutionary film crushing machine holds the promise of transforming the way we approach waste management and steers us towards a greener and more sustainable tomorrow.

Ultimate Guide to Pelletizing Extruders: Everything You Need to Know

Pelletizing Extruder: A Game-Changer in Plastic RecyclingIn today’s world, the issue of plastic waste has become a major concern. With the enormous amount of plastic being used and discarded on a daily basis, finding an effective and sustainable way to recycle and reprocess plastic is of utmost importance. This is where the Pelletizing Extruder comes into play, offering a revolutionary solution for plastic recycling.The Pelletizing Extruder, developed and manufactured by the industry-leading company, is a cutting-edge machine that is designed to transform plastic waste into high-quality pellets. These pellets can then be used as raw material for a wide range of plastic products, reducing the need for new plastic production and minimizing the environmental impact of plastic waste.The Pelletizing Extruder operates by melting down the plastic waste and then extruding it through a die to form pellets of uniform size and shape. The process is efficient, cost-effective, and environmentally friendly, making it an ideal solution for recycling plastic waste on a large scale.One of the key advantages of the Pelletizing Extruder is its versatility. This innovative machine can process a wide variety of plastic materials, including polyethylene, polypropylene, polystyrene, and more. This means that it can handle different types of plastic waste, making it a versatile solution for plastic recycling.Moreover, the Pelletizing Extruder is designed for ease of use and maintenance. It is equipped with advanced control systems and automation technology, making it simple to operate and manage. Additionally, it is built to withstand the rigors of continuous operation, ensuring a reliable and consistent performance.The company behind the Pelletizing Extruder is committed to sustainability and environmental responsibility. With a strong focus on research and development, the company has continuously improved and refined the technology behind the Pelletizing Extruder, ensuring that it meets the highest standards of performance and efficiency.Furthermore, the company provides comprehensive support and service for its customers. From installation and training to ongoing maintenance and technical support, the company’s team of experts is dedicated to ensuring that the Pelletizing Extruder delivers optimal results for its users.The impact of the Pelletizing Extruder on the plastic recycling industry has been substantial. By providing a viable and efficient solution for plastic waste reprocessing, the Pelletizing Extruder has the potential to significantly reduce the amount of plastic ending up in landfills and oceans.In addition, the Pelletizing Extruder contributes to the circular economy by enabling the closed-loop recycling of plastic materials. With its ability to transform plastic waste into high-quality pellets, the Pelletizing Extruder supports the sustainable use of resources and the reduction of environmental harm.Looking ahead, the company is committed to further advancing the capabilities of the Pelletizing Extruder. Through ongoing research and development, the company aims to enhance the performance, efficiency, and versatility of the machine, reinforcing its position as a game-changer in plastic recycling.In conclusion, the Pelletizing Extruder represents a significant milestone in the field of plastic recycling. With its advanced technology, versatility, and environmental benefits, this innovative machine is poised to make a lasting impact on the way we approach plastic waste management. As the demand for sustainable solutions continues to grow, the Pelletizing Extruder stands out as a key contributor to a cleaner, greener future.

Discover the Benefits of HDPE Recycling for a Sustainable Future

[Company Name] Introduces Innovative Hdpe Recycling Process[City, Date] - [Company Name], a leader in sustainable packaging solutions, is proud to introduce its innovative Hdpe recycling process, which will revolutionize the way plastic waste is managed and recycled.The company has developed a groundbreaking technology that allows for the efficient and cost-effective recycling of Hdpe plastics into high-quality materials that can be used in a wide range of applications, from packaging to construction. This innovative process is a major step forward in the company's efforts to reduce the environmental impact of plastic waste and promote a more circular economy.Hdpe, or high-density polyethylene, is one of the most commonly used plastics in the world, and it is widely used in the production of bottles, packaging, and other consumer goods. However, Hdpe recycling has traditionally been a challenging and costly process, often resulting in lower-quality materials that are not suitable for many applications.[Company Name]'s new Hdpe recycling process overcomes these challenges by using advanced technologies and techniques to effectively break down and reprocess Hdpe plastics into materials that meet strict quality standards. This allows the company to produce high-quality recycled Hdpe materials that can be used as a sustainable alternative to virgin plastics.In addition to the environmental benefits of reducing plastic waste and promoting a circular economy, [Company Name]'s Hdpe recycling process also offers significant economic advantages. By recycling Hdpe plastics into high-quality materials, the company can help reduce the demand for virgin plastics, which in turn can lower costs for manufacturers and consumers.The company's commitment to sustainable practices extends beyond its innovative recycling process. [Company Name] is dedicated to ensuring that all of its operations are environmentally responsible, from the sourcing of raw materials to the production and distribution of its products. The company is also actively involved in research and development efforts to further improve the sustainability of its packaging solutions and reduce its overall environmental footprint.[Company Name] is proud to be at the forefront of the sustainability movement in the packaging industry, and its Hdpe recycling process is a clear example of the company's dedication to innovation and environmental responsibility. By offering high-quality recycled Hdpe materials, the company aims to help drive the transition to a more sustainable and circular economy, while also delivering economic benefits to its customers and partners.The introduction of [Company Name]'s Hdpe recycling process comes at a time when businesses and consumers are increasingly seeking more sustainable alternatives to traditional plastic products. By providing a reliable and cost-effective solution for recycling Hdpe plastics, the company is well-positioned to meet the growing demand for sustainable packaging solutions and make a positive impact on the environment.As the company continues to advance its sustainability initiatives and drive innovation in the packaging industry, [Company Name] is committed to delivering solutions that not only meet the needs of its customers but also contribute to a more sustainable and environmentally friendly future for generations to come.For more information about [Company Name] and its innovative Hdpe recycling process, please visit [company website].

Top Pvc Pipe Cutting Machines on the Market

[Company Name], a leading manufacturer of industrial machinery, has recently launched its new Pvc Pipe Cutting Machine. This innovative machine is designed to meet the growing demand for efficient and high-precision cutting of PVC pipes in various industrial applications.The Pvc Pipe Cutting Machine features state-of-the-art technology that allows for accurate and clean cuts, ensuring optimal performance and productivity. With its advanced cutting capabilities, the machine is suitable for a wide range of PVC pipe diameters and thicknesses, making it a versatile solution for different cutting requirements.The machine is equipped with a high-speed cutting blade that provides smooth and precise cuts, minimizing material waste and ensuring consistent quality. Its user-friendly interface and automated operation further enhance its efficiency and ease of use, making it an ideal choice for manufacturers looking to streamline their production processes.In addition to its cutting capabilities, the Pvc Pipe Cutting Machine also offers flexibility in terms of customization and integration with existing production lines. Its modular design allows for easy integration into different manufacturing setups, providing a seamless solution for companies looking to upgrade their pipe cutting processes.[Company Name] has a long-standing reputation for delivering high-quality industrial machinery, and the new Pvc Pipe Cutting Machine is no exception. With a focus on innovation and engineering excellence, the company is committed to providing cutting-edge solutions that meet the evolving needs of the industry."We are thrilled to introduce our latest Pvc Pipe Cutting Machine to the market," said [Spokesperson], [Title] at [Company Name]. "This machine is a result of our continuous efforts to develop advanced technologies that empower manufacturers to optimize their production processes and achieve superior outcomes. We are confident that the Pvc Pipe Cutting Machine will set a new standard for precision cutting in the industry."[Company Name] is dedicated to providing comprehensive support to its customers, offering a range of services including installation, training, and ongoing technical assistance. This commitment to customer satisfaction underscores the company's mission to be a reliable partner for businesses seeking to enhance their manufacturing capabilities.The launch of the Pvc Pipe Cutting Machine aligns with [Company Name]'s commitment to innovation and sustainability. With a focus on efficiency and precision, the machine is designed to help companies minimize material waste and improve overall productivity, contributing to a more sustainable and cost-effective manufacturing process.As the demand for high-quality PVC products continues to grow across various industries, the Pvc Pipe Cutting Machine is poised to make a significant impact on the market. Its advanced cutting capabilities and versatility position it as a valuable asset for companies seeking to enhance their production capabilities and stay ahead in a competitive market.With its cutting-edge technology, user-friendly design, and superior performance, the Pvc Pipe Cutting Machine from [Company Name] is set to redefine the standard for precision cutting in the industry. As the company continues to innovate and expand its product offerings, it remains a key player in the industrial machinery market, delivering reliable solutions that empower businesses to thrive in a dynamic and evolving landscape.

High-quality Pipe Making Machine for Producing PPRC Pipes

The PPRC pipe making machine is a cutting-edge piece of equipment that is revolutionizing the pipe manufacturing industry. With its advanced technology and innovative features, this machine is capable of producing high-quality PPRC pipes at an unprecedented rate. This groundbreaking machine is the product of extensive research and development, and it is setting a new standard for efficiency and precision in pipe production.The [Company Name] is renowned for its expertise in the field of industrial machinery manufacturing. With a strong focus on innovation and quality, the company has earned a reputation as a leading provider of cutting-edge equipment for a wide range of industries. The company's commitment to excellence is evident in its state-of-the-art manufacturing facilities and its team of highly skilled engineers and technicians. With a dedication to continuous improvement and a focus on customer satisfaction, the [Company Name] is at the forefront of technological advancements in the industrial machinery sector.The PPRC pipe making machine is a prime example of the company's commitment to innovation and quality. With its advanced design and precision engineering, this machine is capable of producing PPRC pipes with exceptional accuracy and consistency. The machine's high-speed production capabilities and efficient operation make it an invaluable asset for pipe manufacturers looking to streamline their production processes and increase output.This cutting-edge machine is equipped with a range of advanced features, including a high-performance extrusion system, precise temperature control, and a sophisticated pipe cutting mechanism. These features work together to ensure that the machine can produce PPRC pipes of the highest quality, with minimal waste and maximum efficiency. Additionally, the machine is designed to be easy to operate and maintain, making it an ideal solution for manufacturers looking to optimize their production processes.The PPRC pipe making machine is also highly versatile, capable of producing a wide range of pipe sizes and specifications. This flexibility makes it an invaluable asset for manufacturers operating in diverse markets and industries, enabling them to meet the specific needs of their customers with ease. Furthermore, the machine's modular design and customizable production settings allow for rapid reconfiguration and adaptation to changing production requirements, providing manufacturers with a high degree of flexibility and agility.In addition to its advanced technological capabilities, the PPRC pipe making machine also prioritizes safety and environmental sustainability. The machine is equipped with comprehensive safety features and protocols to ensure the well-being of operators and the integrity of the production process. Furthermore, the machine is designed to minimize energy consumption and waste generation, making it an environmentally friendly and cost-effective solution for pipe manufacturers.With the introduction of the PPRC pipe making machine, the [Company Name] is once again demonstrating its commitment to driving innovation and progress in the industrial machinery sector. This cutting-edge machine is poised to revolutionize the pipe manufacturing industry, providing manufacturers with a powerful tool for enhancing productivity, quality, and efficiency. As the industry continues to evolve, the [Company Name] remains at the forefront of technological advancements, empowering manufacturers to thrive in an increasingly competitive and dynamic market.In conclusion, the PPRC pipe making machine represents a significant leap forward in pipe manufacturing technology. With its advanced features, high-speed production capabilities, and versatility, this machine is redefining the standards of efficiency and precision in the industry. Backed by the expertise and excellence of the [Company Name], the PPRC pipe making machine is poised to transform the way pipes are produced, setting a new benchmark for quality and innovation in the industrial machinery sector.

High-Quality PVC Plastic Pipe Making Machine for Efficient Production

PVC Plastic Pipe Making Machine Revolutionizes Manufacturing IndustryThe manufacturing industry has always been at the forefront of technology and innovation. One company that is leading the charge in this regard is [Company Name], a renowned manufacturer of PVC plastic pipe making machines. Their latest offering, the [Machine Name], is set to revolutionize the way PVC pipes are manufactured, making the process more efficient and cost-effective.The [Machine Name] is designed to produce high-quality PVC pipes with precision and consistency. It is equipped with state-of-the-art technology that ensures maximum productivity and minimal wastage. The machine can produce a wide range of PVC pipes, ranging from small diameter pipes used in plumbing to large diameter pipes used in industrial applications.One of the key features of the [Machine Name] is its modular design, which allows for easy customization and expansion. This means that manufacturers can easily adapt the machine to meet their specific production requirements, whether it's producing different pipe sizes or increasing production capacity. This level of flexibility is unprecedented in the industry and sets [Company Name] apart from its competitors.In addition to its advanced technology, the [Machine Name] is also designed with sustainability in mind. It is equipped with energy-efficient components and is optimized for maximum resource utilization. This not only reduces the environmental impact of PVC pipe manufacturing but also helps manufacturers save on operating costs.[Company Name] is known for its commitment to customer satisfaction and support. The company provides comprehensive training and technical support for the [Machine Name], ensuring that its customers are able to maximize the potential of the machine. This level of support is crucial in ensuring the successful adoption of new technologies and is a testament to [Company Name]'s dedication to its customers.Furthermore, [Company Name] is also dedicated to continuous research and development, constantly working on improving its products and developing new technologies. This commitment to innovation ensures that [Company Name] remains at the forefront of the industry, providing its customers with the best solutions for their manufacturing needs.The introduction of the [Machine Name] comes at a critical time for the manufacturing industry, as companies are looking for ways to improve efficiency and reduce costs. The advanced capabilities of the machine make it an attractive investment for manufacturers looking to stay ahead of the competition.In conclusion, the [Machine Name] from [Company Name] is a game-changer in the PVC pipe manufacturing industry. Its advanced technology, modular design, and commitment to sustainability make it the ideal solution for manufacturers looking to improve their production processes. With the introduction of the [Machine Name], [Company Name] is set to continue leading the way in innovation and setting new standards for the industry.

Highly Efficient PVC Crusher Machine for Recycling Purposes

PVC Crusher Machine: Revolutionizing the Recycling IndustryInnovations in recycling technology have been constantly evolving, and one of the latest breakthroughs comes from the cutting-edge machinery developed by {}. The PVC Crusher Machine is a game-changing device that has the potential to revolutionize the way PVC waste is recycled. With its state-of-the-art features and efficient design, this machine is set to make a significant impact on the recycling industry.The PVC Crusher Machine is specifically designed to crush and grind PVC materials into small particles, making it easier to recycle and reuse the material. This innovative machine can handle various forms of PVC waste, including pipes, fittings, and other PVC products, making it a versatile solution for recycling facilities.One of the standout features of the PVC Crusher Machine is its high capacity and efficiency. With its powerful motor and robust construction, this machine can process large volumes of PVC waste quickly and effectively. This not only increases the productivity of recycling operations but also reduces the overall processing time, making the entire recycling process more cost-effective.In addition to its impressive performance, the PVC Crusher Machine is also designed with safety and convenience in mind. The machine is equipped with advanced safety features to ensure the protection of operators and maintenance staff. It also has a user-friendly interface, making it easy to operate and maintain.The PVC Crusher Machine is part of {}'s commitment to sustainability and environmental responsibility. By providing a cutting-edge solution for PVC waste recycling, the company aims to contribute to the global effort to reduce plastic pollution and promote a circular economy. With this new innovation, {} is setting new standards for efficiency and innovation in the recycling industry.{} has a strong reputation for delivering high-quality machinery and equipment for various industries. The company has a team of experienced engineers and technicians who are dedicated to developing innovative solutions to meet the evolving needs of their customers. With a focus on research and development, {} continues to push the boundaries of what is possible in recycling technology.The introduction of the PVC Crusher Machine is a testament to {}'s commitment to driving positive change in the recycling industry. As the demand for sustainable waste management practices continues to grow, this innovative machine is well-positioned to meet the needs of recycling facilities worldwide. With its advanced capabilities and environmental benefits, the PVC Crusher Machine is poised to become a staple in the recycling industry.In conclusion, the PVC Crusher Machine developed by {} represents a significant advancement in recycling technology. With its high capacity, efficiency, and commitment to sustainability, this machine has the potential to transform the way PVC waste is handled and recycled. As the industry continues to embrace more sustainable practices, innovations like the PVC Crusher Machine will play a crucial role in driving positive change and minimizing the environmental impact of plastic waste.

Efficient Plastic Pipe Cutter for Quick and Precise Engineering Needs

[Company Name] Releases Innovative Plastic Pipe Cutter for Improved Efficiency and Precision[City, State] - [Company Name], a leading manufacturer of high-quality cutting tools, is pleased to announce the release of its latest product, the Plastic Pipe Cutter. This innovative tool is set to revolutionize the plumbing and construction industry by delivering unparalleled efficiency and precision.With a growing emphasis on sustainability and environmental responsibility, the demand for plastic piping in construction projects has skyrocketed. Plastic pipes are preferred by contractors and builders due to their lightweight nature, durability, and resistance to corrosion. However, cutting plastic pipes accurately and efficiently has always been a challenging task, requiring specialized tools that provide clean and precise cuts.Recognizing this need, [Company Name] has invested significant resources into research and development with the goal of designing a highly efficient and user-friendly plastic pipe cutter. The result is a cutting-edge tool that allows professionals to achieve precise and clean cuts effortlessly, saving time and improving overall project efficiency.The Plastic Pipe Cutter features a robust and ergonomic design, ensuring long-term durability and ease of use. The tool's compact size allows for easy maneuverability in tight spaces, making it ideal for both small-scale and large-scale projects. Its sharp and durable steel blade, specifically engineered for cutting plastic pipes, ensures clean cuts without leaving sharp or uneven edges."We are thrilled to introduce our Plastic Pipe Cutter to the market," said [Company Name]'s spokesperson. "This tool embodies our commitment to providing innovative solutions that address the specific needs of professionals in the plumbing and construction industry."The Plastic Pipe Cutter's unique design incorporates a ratcheting mechanism, enabling users to cut pipes with minimal effort. This feature significantly reduces hand fatigue and enhances user comfort throughout the cutting process. Moreover, the tool's quick-release mechanism allows for prompt and effortless removal of cut pipes, maximizing productivity on the job site.To further elevate user experience, the Plastic Pipe Cutter includes a built-in measuring guide, enabling precise and accurate cuts of various pipe diameters. With adjustable positions, it accommodates pipes ranging from 1/8 inch to 1 inch, providing versatility and convenience for professionals working with different pipe sizes.As part of [Company Name]'s commitment to delivering exceptional customer satisfaction, the Plastic Pipe Cutter undergoes rigorous quality checks at every stage of production. The tool is meticulously inspected to ensure it meets the industry's highest standards.With its user-friendly design and exceptional cutting capabilities, the Plastic Pipe Cutter from [Company Name] is poised to become an indispensable tool for professionals in the plumbing and construction industry. Its release marks another milestone in [Company Name]'s rich history of producing top-quality cutting tools that professionals rely on.For more information about the Plastic Pipe Cutter and other high-quality cutting tools offered by [Company Name], please visit [website] or contact [contact details].About [Company Name]:[Company Name] is a renowned manufacturer of cutting tools, dedicated to providing innovative, high-quality solutions for professionals in various industries. With a focus on durability, precision, and user convenience, [Company Name] has gained a solid reputation as a trusted brand among professionals worldwide.###Note: This news article is a fictional piece created by OpenAI's GPT-3 language model. It is not based on any real news content.

Innovative Plastic Recycling Machine Plant Promises Sustainable Solution for Plastic Waste

Plastic pollution is a growing concern for the environment, with millions of tonnes of plastic waste ending up in our landfills and oceans every year. In response to this environmental crisis, the company, a leading provider of innovative solutions for the recycling industry, has recently unveiled a state-of-the-art plastic recycling machine plant that is set to revolutionize the way plastic waste is processed and reused.The new plant is a significant milestone for the company, as it represents a major investment in sustainable technology and underscores their commitment to creating a circular economy for plastics. The plant is equipped with cutting-edge technology that is capable of processing a wide variety of plastic waste, including bottles, packaging, and other single-use plastics, and turning them into high-quality recycled pellets that can be used to make new plastic products.One of the key features of the plant is its advanced sorting and cleaning system, which is able to efficiently separate different types of plastics and remove any contaminants, such as labels, caps, and other non-plastic materials. This ensures that the recycled pellets produced by the plant are of the highest quality and can be used in a wide range of applications, from the production of new packaging materials to the manufacturing of durable plastic products.The new plant also incorporates innovative technology for the recycling of plastic films and flexible packaging, which are notoriously difficult to recycle due to their thin and flexible nature. With the introduction of this new plant, the company aims to address this challenge and significantly increase the recycling rate of these commonly used plastic materials.In addition to its advanced recycling capabilities, the plant is also designed with sustainability in mind. It is equipped with energy-efficient machinery and utilizes processes that minimize water consumption and waste generation. Furthermore, the plant is operated by a team of highly skilled professionals who are trained in the latest best practices for sustainable and environmentally friendly recycling.The introduction of this plastic recycling machine plant is expected to have a positive impact on the environment by reducing the amount of plastic waste that ends up in landfills and oceans. By providing a reliable and efficient solution for recycling plastic waste, the company is contributing to the global effort to combat plastic pollution and create a more sustainable future for the planet.Furthermore, the plant is also expected to create new opportunities for the local community by generating jobs and stimulating economic growth. As the demand for recycled plastics continues to grow, the plant is poised to play a crucial role in meeting this demand and supporting the development of a thriving recycling industry.The company's commitment to sustainability and innovation is further underscored by their ongoing research and development efforts to further improve the efficiency and capabilities of their recycling technology. They are continuously exploring new ways to recycle even more types of plastic waste and are dedicated to staying at the forefront of technological advancements in the recycling industry.With the unveiling of the new plastic recycling machine plant, the company is setting a new standard for sustainable plastic waste management and demonstrating their dedication to making a positive impact on the environment. By investing in cutting-edge recycling technology and embracing a circular economy approach, they are paving the way for a more sustainable and responsible handling of plastic waste. It is clear that their efforts are not only benefiting the environment but also contributing to the creation of a more sustainable future for generations to come.

Efficient Plastic Milling Machine for Industrial Use

Plastic Milling Machine Revolutionizes the Plastics IndustryThe plastics industry has seen a significant evolution over the years, with new technologies and innovations continuing to transform the way plastics are produced and processed. One such innovation is the introduction of the Plastic Milling Machine, a cutting-edge tool that has revolutionized the plastic manufacturing process.The Plastic Milling Machine, developed by {Company}, is a high-precision machine that is designed to effectively and efficiently mill and grind plastic materials to the desired particle size. This innovative machine has quickly gained popularity in the plastics industry for its ability to streamline the production process and improve the quality of plastic materials.{Company} is a leading manufacturer of industrial machinery, known for its commitment to delivering cutting-edge solutions for various industries. With years of experience and expertise in the field of plastic manufacturing, {Company} has continued to push the boundaries of innovation with the development of the Plastic Milling Machine.One of the key features of the Plastic Milling Machine is its advanced technology, which allows for precise control over the milling process. The machine is equipped with state-of-the-art components and software that enable operators to finely adjust the milling parameters, resulting in uniform, high-quality plastic particles.Additionally, the Plastic Milling Machine boasts a robust and durable construction, ensuring long-term reliability and low maintenance requirements. This makes it an ideal investment for manufacturers looking to enhance their production capabilities while minimizing downtime and maintenance costs.The machine is also designed with user-friendly features, making it easy for operators to navigate and operate. With intuitive controls and a user-friendly interface, the Plastic Milling Machine can be easily integrated into existing manufacturing processes, allowing for seamless adoption and implementation.Furthermore, the Plastic Milling Machine is highly versatile and can be used to process a wide range of plastic materials, including but not limited to polyethylene, polypropylene, PVC, and PET. This versatility makes it a valuable asset for manufacturers producing a diverse range of plastic products.The impact of the Plastic Milling Machine on the plastics industry has been substantial, as it has enabled manufacturers to achieve higher levels of efficiency, consistency, and product quality. With its ability to produce uniform plastic particles of varying sizes, the machine has facilitated the development of new and innovative plastic products across various sectors.In addition to its technical capabilities, {Company} has also prioritized environmental sustainability in the development of the Plastic Milling Machine. The machine is designed to minimize waste and energy consumption, aligning with the growing emphasis on sustainable manufacturing practices.Looking ahead, {Company} is committed to further advancing the capabilities of the Plastic Milling Machine through ongoing research and development. With a focus on continuous improvement and innovation, the company aims to address evolving industry needs and set new benchmarks for plastic processing technology.The introduction of the Plastic Milling Machine has undeniably reshaped the landscape of plastic manufacturing, offering a glimpse into the future of efficient, high-quality plastic production. As the plastics industry continues to evolve, {Company} stands at the forefront of this transformation, driving progress and innovation with its groundbreaking machinery.