High-Quality PPR Pipe Making Machine for Efficient Production

By:Admin

The PPR pipe making machines produced by the company are known for their precision engineering, advanced technology, and durable construction. They are designed to meet the specific requirements of PPR pipe production, ensuring high productivity and superior quality output. The machines are also equipped with the latest automation and control systems, enabling seamless operation and easy maintenance.

One of the key features of the PPR pipe making machines from (need remove brand name) is their versatility. They can produce a wide range of PPR pipe sizes and specifications, making them suitable for different customer needs and production demands. Whether it's small diameter pipes for residential plumbing or large diameter pipes for industrial applications, the machines are capable of delivering consistent and reliable performance.

The company takes great pride in its commitment to research and development, constantly innovating and improving its machines to meet the evolving needs of the PPR pipe industry. This dedication to advancement has enabled them to stay ahead of the competition and maintain their position as a trusted and preferred supplier of PPR pipe making machines.

In addition to its technological expertise, (need remove brand name) also places great emphasis on customer satisfaction. The company has a team of experienced engineers and technicians who provide comprehensive support to customers, from machine installation and commissioning to after-sales service and technical assistance. This customer-centric approach has earned (need remove brand name) a loyal and satisfied customer base, with many customers returning for repeat purchases and recommending the company to others.

Furthermore, the company takes its environmental responsibilities seriously, and all of its PPR pipe making machines are designed to be energy-efficient and eco-friendly. By optimizing energy consumption and minimizing waste, (need remove brand name) contributes to a more sustainable and greener manufacturing process, aligning with the global push for environmental conservation.

In line with its commitment to excellence, (need remove brand name) has obtained various certifications and accreditations, attesting to the quality and reliability of its PPR pipe making machines. These certifications include ISO 9001 for quality management and CE for compliance with European standards, further demonstrating the company's adherence to stringent quality and safety standards.

Looking ahead, (need remove brand name) aims to continue its leadership in the PPR pipe making machine industry by staying at the forefront of technological advancements and customer satisfaction. The company remains dedicated to providing innovative, efficient, and sustainable solutions to its customers, contributing to the growth and success of the global PPR pipe manufacturing sector.

In conclusion, (need remove brand name) is a trusted and respected manufacturer of PPR pipe making machines, known for its advanced technology, precision engineering, and commitment to customer satisfaction. With a strong track record of delivering high-performance machines and comprehensive support services, the company is poised to maintain its position as a preferred partner for PPR pipe manufacturers worldwide.

Company News & Blog

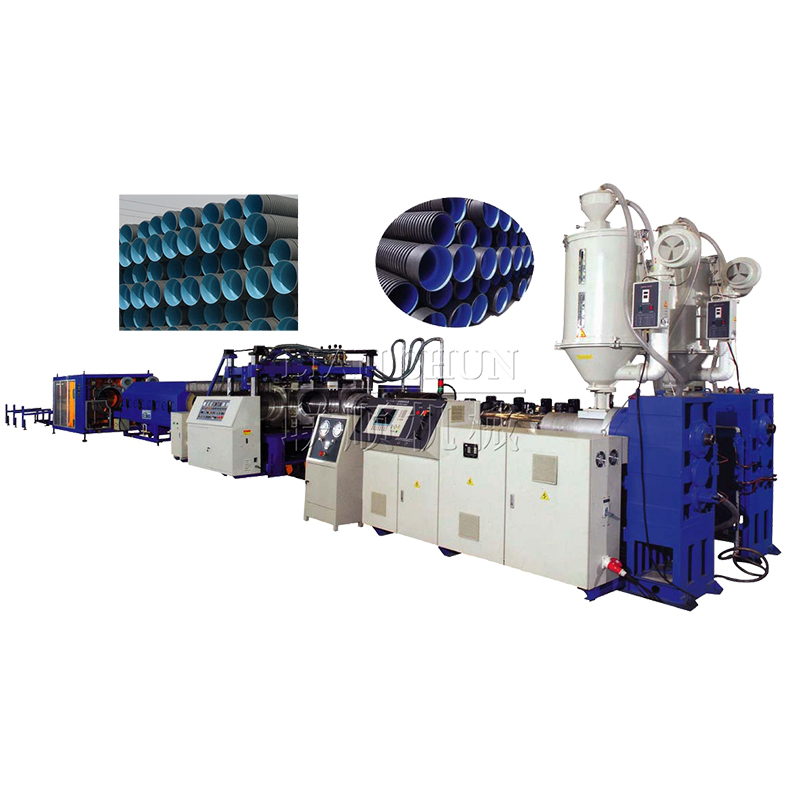

Ultimate Guide to HDPE Corrugated Pipe Machine: Everything You Need to Know

Innovative HDPE Corrugated Pipe Machine Revolutionizes Production ProcessThe plastic pipe industry has been revolutionized by the latest HDPE Corrugated Pipe Machine introduced by leading plastic extrusion machinery manufacturer {}. With an unwavering commitment to providing innovative solutions to the plastic processing industry, {} has once again raised the bar with its state-of-the-art HDPE Corrugated Pipe Machine.The new HDPE Corrugated Pipe Machine is designed to meet the growing demand for high-quality, durable, and cost-effective plastic piping solutions. By leveraging advanced extrusion technology, the machine is capable of producing high-density polyethylene (HDPE) corrugated pipes with exceptional precision and efficiency. This groundbreaking development is set to address the challenges faced by the industry in meeting the growing demands for infrastructure development, water management, and environmental protection.The HDPE Corrugated Pipe Machine boasts a range of cutting-edge features that set it apart from conventional plastic extrusion machinery. With its advanced screw design and high-performance motor, the machine ensures a consistent and reliable production process, resulting in pipes with superior structural integrity and performance. Furthermore, the machine is equipped with a precision control system that allows for seamless adjustments in pipe diameter, thickness, and length, catering to a diverse range of project requirements.In addition to its technical capabilities, the HDPE Corrugated Pipe Machine also offers unparalleled operational efficiency. Its innovative design minimizes energy consumption and reduces material wastage, translating to significant cost savings for manufacturers. This enhanced productivity and resource optimization are instrumental in driving sustainable practices within the plastic pipe industry.Furthermore, the machine is designed for ease of operation and maintenance, ensuring a seamless production process for manufacturers. Its user-friendly interface and intuitive controls make it accessible to operators of varying skill levels, while its robust construction and minimal maintenance requirements contribute to its long-term reliability and cost-effectiveness.Commenting on the introduction of the HDPE Corrugated Pipe Machine, a spokesperson for {} stated, "We are proud to unveil this groundbreaking addition to our product portfolio. With the increasing demand for high-performance plastic piping solutions, it is imperative for manufacturers to have access to cutting-edge technology that enables them to meet and exceed industry standards. Our new HDPE Corrugated Pipe Machine is a testament to our commitment to innovation and sustainability, and we are confident that it will revolutionize the plastic pipe manufacturing process."The introduction of the HDPE Corrugated Pipe Machine is expected to have a profound impact on the plastic pipe industry, as manufacturers seek to capitalize on its advanced capabilities and operational efficiencies. By setting new benchmarks in production quality, cost-effectiveness, and environmental sustainability, the machine is poised to drive significant advancements in the development and deployment of plastic piping solutions across various applications.As the industry embraces the new era of plastic pipe production facilitated by the HDPE Corrugated Pipe Machine, manufacturers are presented with an opportunity to elevate their competitive edge and deliver enhanced products to meet the evolving needs of infrastructure, construction, and environmental sectors. With its game-changing features and performance, the machine is poised to redefine the standards of plastic pipe manufacturing, paving the way for a more efficient, sustainable, and resilient industry.

Highly Efficient Plastic Crusher Machine for Your Recycling Needs

Plastic pollution has become a major environmental issue around the world, causing harm to wildlife, ecosystems, and human health. In response to this pressing issue, {Company Name} has introduced a state-of-the-art Plastic Crusher Machine designed to effectively reduce plastic waste.{Company Name} is a leading manufacturer of environmental protection equipment, with a deep commitment to sustainability and innovation. With over 20 years of experience in the industry, the company has continuously strived to develop cutting-edge solutions to combat environmental challenges.The newly introduced Plastic Crusher Machine is a powerful and efficient device that is capable of shredding and crushing various types of plastic waste, including bottles, film, and other plastic materials. The machine is designed to make the recycling process easier and more efficient, ultimately reducing the amount of plastic waste that ends up in landfills or polluting our oceans and rivers.One of the key features of the {Company Name} Plastic Crusher Machine is its strong and durable construction, ensuring long-term reliability and performance. Its robust design allows it to handle large volumes of plastic waste, making it suitable for both industrial and commercial applications. Additionally, the machine is equipped with advanced technology to efficiently grind and process plastic materials, resulting in high-quality output that can be easily recycled.In addition to its powerful capabilities, the Plastic Crusher Machine is also designed with safety and ease of use in mind. It is equipped with safety features to prevent accidents and ensure the protection of operators. Furthermore, the machine is user-friendly, with simple controls and easy maintenance procedures, making it accessible for a wide range of users.{Company Name} is dedicated to providing comprehensive support and service for its Plastic Crusher Machine, including installation, training, and ongoing maintenance to ensure its optimal performance. The company takes pride in its commitment to delivering high-quality products and reliable service to its customers, helping them achieve their sustainability goals and contribute to a cleaner, greener environment.The introduction of the Plastic Crusher Machine is aligned with {Company Name}'s mission to develop innovative solutions that address environmental challenges. By offering a powerful and efficient tool for plastic waste management, the company aims to support the global efforts to reduce plastic pollution and promote a circular economy that prioritizes recycling and reusing plastic materials.As the demand for sustainable solutions continues to grow, {Company Name} remains at the forefront of environmental protection technology, continuously striving to develop and improve its products to meet the evolving needs of its customers and contribute to a more sustainable future.With its strong commitment to sustainability, innovation, and customer satisfaction, {Company Name} is poised to make a significant impact in the fight against plastic pollution with its Plastic Crusher Machine. As the world continues to grapple with the consequences of plastic waste, innovative solutions such as this will play a crucial role in mitigating the environmental impact and creating a more sustainable, cleaner planet for future generations.

High Quality Pp Ppr Pe Pvc Pipe Extruder Machine for Efficient Pipe Production

[Company Name] Launches New Pp Ppr Pe Pvc Pipe Extruder Machine[City, State] – [Company Name], a leading manufacturer of plastic extrusion machinery, is proud to announce the launch of their latest product, the Pp Ppr Pe Pvc Pipe Extruder Machine. This advanced machine is designed to meet the growing demand for high-quality plastic pipe products in the construction and infrastructure sectors.The new Pp Ppr Pe Pvc Pipe Extruder Machine is a state-of-the-art extrusion system that is capable of producing a wide range of plastic pipes, including polypropylene (Pp), polyethylene (Pe), polyvinyl chloride (Pvc), and polypropylene-random (Ppr) pipes. The machine features advanced technology and precision engineering, allowing for efficient and consistent production of pipes with a high degree of accuracy and quality.With the increasing emphasis on sustainable and durable piping solutions, the Pp Ppr Pe Pvc Pipe Extruder Machine is well-positioned to meet the needs of the market. It is capable of processing a variety of raw materials, including recycled plastics, to produce pipes that are not only strong and reliable but also environmentally friendly.[Company Name] has a long-standing reputation for delivering cutting-edge extrusion machinery to the plastic manufacturing industry. With a commitment to innovation and excellence, the company has continuously invested in research and development to create advanced solutions for their customers. The launch of the Pp Ppr Pe Pvc Pipe Extruder Machine is a testament to [Company Name]'s dedication to providing state-of-the-art equipment that meets the evolving needs of the industry.The new extruder machine is designed to offer maximum production efficiency while minimizing energy consumption and waste. Its user-friendly interface and automated features make it easy to operate, allowing for seamless integration into existing production lines. This will enable manufacturers to streamline their processes and increase their output without compromising on the quality of their products.In addition to its technical capabilities, the Pp Ppr Pe Pvc Pipe Extruder Machine is backed by [Company Name]'s stellar customer support and after-sales service. The company's team of experts is available to provide comprehensive training, technical assistance, and maintenance services to ensure that their customers can fully optimize the performance of the machine."We are excited to introduce the Pp Ppr Pe Pvc Pipe Extruder Machine to the market," said [Spokesperson Name], [Title] of [Company Name]. "This machine represents the culmination of our efforts to provide our customers with the most advanced and reliable extrusion technology. We believe it will empower manufacturers to meet the growing demand for high-quality plastic pipes while contributing to a more sustainable and efficient industry."As the demand for plastic pipes continues to rise, [Company Name] remains at the forefront of delivering innovative solutions to the market. The launch of the Pp Ppr Pe Pvc Pipe Extruder Machine underscores [Company Name]'s leadership in the plastic extrusion industry and its commitment to driving the progress of the sector.For more information about the Pp Ppr Pe Pvc Pipe Extruder Machine and other products offered by [Company Name], visit their website [Company Website].

High-Quality PPR Pipe Making Machine for Efficient Production

Ppr Pipe Making Machine (need remove brand name) is a leading manufacturer of high-quality PPR pipe making machines. The company has been in the industry for over 20 years and has a strong reputation for delivering reliable and efficient equipment to its customers. Their machines are used by pipe manufacturers around the world to produce PPR pipes for various applications such as plumbing, heating, and industrial processes.The PPR pipe making machines produced by the company are known for their precision engineering, advanced technology, and durable construction. They are designed to meet the specific requirements of PPR pipe production, ensuring high productivity and superior quality output. The machines are also equipped with the latest automation and control systems, enabling seamless operation and easy maintenance.One of the key features of the PPR pipe making machines from (need remove brand name) is their versatility. They can produce a wide range of PPR pipe sizes and specifications, making them suitable for different customer needs and production demands. Whether it's small diameter pipes for residential plumbing or large diameter pipes for industrial applications, the machines are capable of delivering consistent and reliable performance.The company takes great pride in its commitment to research and development, constantly innovating and improving its machines to meet the evolving needs of the PPR pipe industry. This dedication to advancement has enabled them to stay ahead of the competition and maintain their position as a trusted and preferred supplier of PPR pipe making machines.In addition to its technological expertise, (need remove brand name) also places great emphasis on customer satisfaction. The company has a team of experienced engineers and technicians who provide comprehensive support to customers, from machine installation and commissioning to after-sales service and technical assistance. This customer-centric approach has earned (need remove brand name) a loyal and satisfied customer base, with many customers returning for repeat purchases and recommending the company to others.Furthermore, the company takes its environmental responsibilities seriously, and all of its PPR pipe making machines are designed to be energy-efficient and eco-friendly. By optimizing energy consumption and minimizing waste, (need remove brand name) contributes to a more sustainable and greener manufacturing process, aligning with the global push for environmental conservation.In line with its commitment to excellence, (need remove brand name) has obtained various certifications and accreditations, attesting to the quality and reliability of its PPR pipe making machines. These certifications include ISO 9001 for quality management and CE for compliance with European standards, further demonstrating the company's adherence to stringent quality and safety standards.Looking ahead, (need remove brand name) aims to continue its leadership in the PPR pipe making machine industry by staying at the forefront of technological advancements and customer satisfaction. The company remains dedicated to providing innovative, efficient, and sustainable solutions to its customers, contributing to the growth and success of the global PPR pipe manufacturing sector.In conclusion, (need remove brand name) is a trusted and respected manufacturer of PPR pipe making machines, known for its advanced technology, precision engineering, and commitment to customer satisfaction. With a strong track record of delivering high-performance machines and comprehensive support services, the company is poised to maintain its position as a preferred partner for PPR pipe manufacturers worldwide.

High-Density Polyethylene Pelletizing Machine - All You Need to Know

Hdpe Pelletizing Machine Revolutionizing Plastic Recycling IndustryThe plastic recycling industry has seen a significant transformation in recent years with the introduction of advanced technologies and machinery aimed at improving the efficiency and quality of recycled plastic materials. One of the latest innovations in this field is the Hdpe Pelletizing Machine, which is set to revolutionize the way plastics are processed and recycled.The Hdpe Pelletizing Machine, developed by a leading manufacturer in the plastic recycling machinery industry, is designed to efficiently process HDPE (High-Density Polyethylene) plastic waste and convert it into high-quality plastic pellets. This innovative machine incorporates advanced technologies and features to optimize the pelletizing process and produce uniform and consistent pellets, making it a game-changer in the plastic recycling industry.With the increasing demand for recycled plastic materials and the growing environmental concerns associated with plastic waste, the Hdpe Pelletizing Machine is poised to make a significant impact on the industry by improving the overall efficiency and productivity of plastic recycling operations. The machine's ability to process HDPE plastic waste into high-quality pellets not only helps reduce the environmental impact of plastic waste but also provides a sustainable solution for the reuse of plastic materials in various industries.The company behind the development of the Hdpe Pelletizing Machine has a strong reputation as a leading manufacturer of plastic recycling machinery, with a focus on providing innovative and sustainable solutions for the industry. With years of experience and expertise in the field, the company has gained recognition for its commitment to delivering high-quality machinery that meets the evolving needs of the plastic recycling industry.In addition to the Hdpe Pelletizing Machine, the company offers a comprehensive range of plastic recycling machinery, including shredders, granulators, washing lines, and extruders, catering to the diverse requirements of plastic recycling operations. The company's dedication to research and development has led to the continuous improvement and innovation of its machinery, ensuring that its customers have access to the latest technologies and advancements in plastic recycling equipment.Furthermore, the company places a strong emphasis on customer satisfaction and support, offering comprehensive services such as technical assistance, installation, and maintenance to ensure the optimal performance and longevity of its machinery. This commitment to customer service has enabled the company to build long-lasting relationships with its clients and establish itself as a trusted partner in the plastic recycling industry.The Hdpe Pelletizing Machine is a testament to the company's ongoing efforts to drive innovation and progress in the plastic recycling industry, as it addresses the need for more efficient and sustainable solutions for plastic waste management. By introducing advanced machinery that can effectively process HDPE plastic waste into high-quality pellets, the company is contributing to the circular economy and promoting the responsible use of plastic materials.As the demand for recycled plastic materials continues to grow, the Hdpe Pelletizing Machine is expected to play a pivotal role in meeting this demand by providing a reliable and efficient solution for processing HDPE plastic waste. With its cutting-edge technology and the company's unwavering commitment to excellence, the Hdpe Pelletizing Machine is set to make a lasting impact on the plastic recycling industry, driving progress and sustainability for years to come.

High-Performance Polythene Extruder Machine: Latest News Updates

Polythene Extruder Machine: Revolutionizing Plastics ManufacturingPlastics have become an essential part of our daily lives, from packaging materials to household items, and even the automotive industry. The demand for high-quality plastics continues to grow, and manufacturers are constantly striving to meet these demands. This is where the Polythene Extruder Machine, developed by a leading industry company, comes into play.With their state-of-the-art technology and innovative approach to plastics manufacturing, the company has become a leader in the industry. Their Polythene Extruder Machine is just one example of their commitment to meeting the ever-growing demand for high-quality plastics.The Polythene Extruder Machine is a crucial component in the process of producing polythene, a versatile and widely used plastic material. The machine works by heating and melting the polythene resin, which is then forced through a die to create a continuous profile. This profile is then cooled and cut into the desired shape and size, resulting in a high-quality plastic product.One of the key features of the Polythene Extruder Machine is its versatility. It can be used to produce a wide range of plastic products, from simple packaging materials to complex components used in various industries. This versatility makes it a valuable asset for manufacturers looking to expand their product offerings and meet the diverse needs of their customers.In addition to its versatility, the Polythene Extruder Machine is also known for its efficiency and precision. The machine is equipped with advanced controls and monitoring systems that ensure consistent and high-quality output. This level of precision is crucial in meeting the strict standards and specifications required by different industries.Moreover, the company behind the Polythene Extruder Machine offers comprehensive support and services to their customers. From installation and training to maintenance and troubleshooting, they are committed to ensuring that their customers get the most out of their investment in the machine. This level of customer support sets them apart from other manufacturers in the industry.Furthermore, the company is dedicated to sustainability and environmental responsibility. They have incorporated several eco-friendly features into the design of the Polythene Extruder Machine, such as energy-efficient components and a reduced environmental footprint. This commitment to sustainability aligns with the growing demand for eco-friendly products and production processes.The Polythene Extruder Machine has already made a significant impact in the plastics manufacturing industry. Many companies have reported increased production efficiency and product quality after implementing this state-of-the-art machine. As the demand for high-quality plastics continues to grow, it is expected that the Polythene Extruder Machine will play a crucial role in meeting these demands.In conclusion, the Polythene Extruder Machine, developed by a leading industry company, is revolutionizing plastics manufacturing. With its versatility, precision, and commitment to sustainability, it has become a valuable asset for companies looking to meet the growing demand for high-quality plastics. As the industry continues to evolve, the Polythene Extruder Machine will undoubtedly remain at the forefront of innovation and excellence in plastics manufacturing.

Top Small Twin Screw Extruder to Consider for Your Needs

The Small Twin Screw Extruder, a new product from a leading manufacturing company in the plastics industry, is set to revolutionize the way plastic materials are processed and manufactured. This innovative machine is designed to provide a cost-effective solution for small-scale production of plastic products, offering high output and exceptional quality. With its compact size and versatility, the Small Twin Screw Extruder is a game-changer for businesses looking to streamline their plastic processing operations.The company, a global leader in the production of plastic extrusion equipment, has a long-standing reputation for delivering cutting-edge solutions to the plastics industry. With a focus on innovation and customer satisfaction, the company has consistently pushed the boundaries of what is possible in plastic processing technology. The Small Twin Screw Extruder is the latest example of the company's commitment to providing its customers with state-of-the-art equipment that meets their specific needs and exceeds their expectations.One of the key features of the Small Twin Screw Extruder is its compact size, making it ideal for small-scale production facilities or research and development laboratories. Despite its small footprint, this machine delivers exceptional performance, with a high output capacity and superior product quality. This makes it the perfect choice for businesses looking to optimize their production processes without compromising on the quality of their products.In addition to its high performance, the Small Twin Screw Extruder is also incredibly versatile. It is capable of processing a wide range of plastic materials, including both virgin and recycled plastics, as well as various additives and fillers. This flexibility allows businesses to produce a diverse range of plastic products with ease, making the Small Twin Screw Extruder a valuable asset for companies operating in a variety of industries.The Small Twin Screw Extruder is also designed with efficiency and ease of use in mind. It features a user-friendly interface and intuitive controls, making it simple for operators to set up and run the machine. This not only improves productivity but also minimizes the risk of human error, ensuring consistent and reliable performance.Furthermore, the Small Twin Screw Extruder is equipped with advanced technology that enhances its overall efficiency and performance. This includes features such as optimized screw geometry and advanced temperature control systems, which work together to ensure precise and uniform processing of plastic materials. As a result, the machine delivers a high-quality end product while minimizing waste and energy consumption.The company behind the Small Twin Screw Extruder is renowned for its dedication to customer service and support. They provide comprehensive training and technical assistance to help their customers get the most out of their equipment. This ensures that businesses are able to maximize the potential of the Small Twin Screw Extruder and achieve the best possible results.Overall, the Small Twin Screw Extruder represents a significant advancement in plastic processing technology. Its combination of high performance, versatility, and user-friendly design makes it an invaluable asset for businesses looking to optimize their plastic processing operations. With the backing of a reputable and innovative company, this machine is set to make a lasting impact on the plastics industry.

Extruder Plastic Pelletizing Line: A Comprehensive Guide

Extruder Plastic Pelletizing Line Revolutionizing the Plastic Manufacturing IndustryIn today's fast-paced world, the demand for quality plastic products is on the rise. Companies are constantly looking for advanced solutions that can help them meet this growing demand. This is where the Extruder Plastic Pelletizing Line comes into play. This innovative technology is revolutionizing the plastic manufacturing industry, enabling companies to produce high-quality plastic pellets efficiently and cost-effectively.The Extruder Plastic Pelletizing Line is the brainchild of a leading company in the plastics industry. With a strong commitment to innovation and excellence, the company has been a driving force in the development of advanced plastic manufacturing technologies. Their team of dedicated engineers and experts have worked tirelessly to create a state-of-the-art pelletizing line that is redefining the way plastics are produced.This cutting-edge technology is designed to streamline the plastic manufacturing process, making it faster, more efficient, and more sustainable. The Extruder Plastic Pelletizing Line is equipped with advanced extrusion and pelletizing components that work seamlessly together to produce uniform and high-quality plastic pellets. This means that companies can now produce plastic pellets with consistent quality and properties, leading to fewer defects and rejections in the production process.The Extruder Plastic Pelletizing Line also offers significant cost savings for companies. By automating and optimizing the plastic manufacturing process, this technology reduces the need for manual labor and minimizes the amount of raw material waste. This not only helps companies save money on production costs, but also promotes a more sustainable and eco-friendly approach to plastic manufacturing.Furthermore, the Extruder Plastic Pelletizing Line is highly versatile and can be customized to meet the specific needs of different industries. Whether it's for the production of packaging materials, construction products, automotive components, or consumer goods, this technology can be tailored to produce plastic pellets that meet the exact requirements of the end-use application.One of the key advantages of the Extruder Plastic Pelletizing Line is its ability to handle a wide range of plastic materials. From polyethylene and polypropylene to PVC and PET, this technology can efficiently process various types of plastics, making it an ideal solution for companies working with diverse materials.Moreover, the Extruder Plastic Pelletizing Line is designed for ease of use and maintenance. The user-friendly interface and intuitive controls make it simple for operators to oversee the production process and make adjustments as needed. Additionally, the line is built with high-quality and durable components, ensuring reliable performance and minimal downtime for maintenance and repairs.In conclusion, the Extruder Plastic Pelletizing Line is a game-changer for the plastic manufacturing industry. Its advanced technology, cost-saving benefits, versatility, and sustainability make it a valuable asset for companies looking to stay ahead in a competitive market. With this innovative solution, companies can enhance their production capabilities, improve product quality, and achieve greater efficiency in their plastic manufacturing operations. As the demand for high-quality plastic products continues to grow, the Extruder Plastic Pelletizing Line is set to play a pivotal role in shaping the future of the industry.

Leading Extruder Manufacturer: Find the Best Extruder Solutions for Your Business

Extruder Manufacturer, a leading provider of high-quality extrusion equipment, is proud to announce the launch of their new and improved line of extruders. With over 20 years of experience in the industry, Extruder Manufacturer has become known for their innovative technologies and dedication to customer satisfaction.Founded in 1998, Extruder Manufacturer has grown from a small operation to a global leader in the extrusion industry. The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce extruders that meet the highest standards of quality and performance.The new line of extruders features several enhancements that have been designed to improve efficiency and productivity for their customers. These improvements include a redesigned screw geometry, advanced cooling systems, and enhanced control systems. These upgrades have been carefully engineered to provide optimal performance and reliability, ensuring that customers can achieve maximum output and profitability.In addition to the technological advancements, Extruder Manufacturer has also focused on improving the overall user experience with their new line of extruders. The company has implemented a user-friendly interface that makes operation and maintenance easier than ever. This will allow customers to spend less time on maintenance and troubleshooting, and more time on production and business growth."We are thrilled to introduce our new line of extruders to the market," said the CEO of Extruder Manufacturer. "We have put a lot of time and effort into developing these machines, and we are confident that they will exceed our customers' expectations. Our goal is to provide our customers with the best tools to help them succeed in their businesses, and we believe that these new extruders will do just that."Extruder Manufacturer's commitment to quality extends beyond their products – it is also reflected in their customer service and support. The company's team of experts is available to provide guidance and assistance to customers, helping them to find the right extruder for their specific needs and requirements. This level of support is just one of the many reasons why Extruder Manufacturer has earned a reputation for excellence in the industry.The launch of the new line of extruders is a significant milestone for Extruder Manufacturer, and the company is excited to see the impact that these machines will have on their customers' businesses. With their focus on innovation, quality, and customer satisfaction, Extruder Manufacturer is poised to continue leading the way in the extrusion industry for years to come.For more information about Extruder Manufacturer and their new line of extruders, visit their website or contact their team directly. With their dedication to excellence and their track record of success, customers can trust Extruder Manufacturer to provide them with the best extrusion solutions available.

High-Quality PVC Pipe Extrusion Machine for Efficient Production

PVC Pipe Extrusion Machine Leads the Industry with Innovation and QualityThe PVC pipe extrusion machine is a vital piece of equipment in the manufacturing of PVC pipes, which are essential components in numerous industries including construction, agriculture, and water supply. The latest advancements in PVC pipe extrusion technology have revolutionized the industry, leading to higher productivity, improved quality, and reduced production costs.One company at the forefront of this innovation is {Company Name}. With a long history of providing top-of-the-line PVC pipe extrusion machines, {Company Name} has established itself as a leader in the field. The company's commitment to research and development has led to the creation of cutting-edge equipment that meets the evolving needs of the industry.The PVC pipe extrusion machine produced by {Company Name} features state-of-the-art technology that ensures precision and efficiency in the extrusion process. The machine is designed to handle a wide range of PVC pipe sizes and specifications, allowing manufacturers to produce pipes that meet the diverse requirements of their customers.One of the key features of {Company Name}'s PVC pipe extrusion machine is its high level of automation, which streamlines the production process and minimizes the need for manual intervention. This results in increased productivity and reduced labor costs, making the machine a valuable investment for PVC pipe manufacturers.In addition to its advanced technology, the PVC pipe extrusion machine from {Company Name} is also known for its exceptional quality and durability. The use of high-quality materials and precision engineering ensures that the machine performs reliably, delivering consistent results with minimal maintenance requirements.Another important aspect of {Company Name}'s PVC pipe extrusion machine is its energy efficiency. The machine is designed to minimize energy consumption, helping manufacturers reduce their operating costs and environmental impact.{Company Name} takes pride in providing comprehensive support to its customers, offering installation, training, and technical assistance to ensure optimal performance of its PVC pipe extrusion machines. The company's team of experienced engineers and technicians are dedicated to helping customers maximize the potential of their equipment.With a strong focus on innovation and customer satisfaction, {Company Name} continues to push the boundaries of PVC pipe extrusion technology. The company's commitment to excellence has earned it a reputation as a trusted partner for PVC pipe manufacturers worldwide.In conclusion, the PVC pipe extrusion machine from {Company Name} represents the latest advancements in technology and quality in the industry. With its innovative features, exceptional performance, and comprehensive support, the machine is a game-changer for PVC pipe manufacturers looking to stay ahead in a competitive market. As the demand for PVC pipes continues to grow, {Company Name} remains at the forefront, providing cutting-edge solutions that meet the evolving needs of the industry.